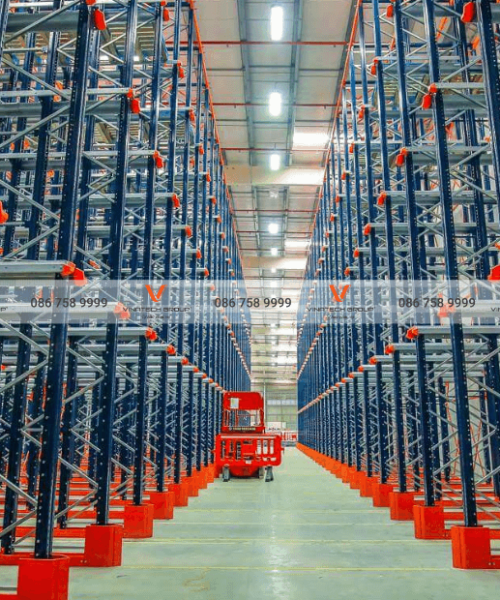

Heavy-duty industrial racks are named bases on the storage characteristics and functions of racks. This is a special type of shelf used to store and preserve goods and supplies in warehouses with a large load such as iron and steel coils, construction materials, electronic components. The image of a warehouse rack for heavy goods is like the one below.

HEAVY DUTY RACKING

Introduction of heavy-duty racks & the important role

What is heavy-duty rack?

Heavy duty racking is a type of rack used to store heavy goods, often used in warehouses. Outstanding heavy-duty stand with sturdy frames, pillars, and large beams. The base is screwed into the floor to make the system more stable.Heavy-duty racking help optimize warehouses very well, increasing storage capacity by 50% – 300%. It helps to optimize the height of the warehouse, divide the floor to store goods, help the warehouse to be neat and tidy.Regarding the load, we can calculate by the number of tier and the number of pallets per tier. The average load of a pallet is 500kg, each tier of the heavy load rack will hold from 2 to 8 pallets. The average total load per tier of heavy-duty racking is from 1000 – 4000 kg/tier. Depending on the condition of the warehouse, the investor can install racks with 2, 3 or up to 5 tiers.

Heavy-duty rack

The role of heavy-duty rack in the warehouse

- Optimize warehouse space effectively.

- Merchandise management is easier.

- Limit loss and damage.

- Forklifts easily enter and pick up goods on rack, saving time and effort.

- Save costs by optimizing resources and timing.

Top 8+ best heavy-duty racks models1

Selective Racking

Selective racking is the most popular shelf in warehouses now. Each tier of rack has a capacity up to 4000kg and we can import and export goods by hand or use forklifts.

Selective heavy-duty features:

- Suitable for forklift aisles from 3 to 3.4m

- Apply FIFO pick up method

- Allow access to any pallet

- Optimized the pallet quantity up to 90%

Selective racking is the most popular shelf in warehouses now

Selective rack of Vinatech Group is manufactured by modern and advanced production lines with diverse sizes according to customers need.

You can trust that Selective rack is designed to fit all type of forklifts. So that, the import and export, moving goods in the warehouse is extremely convenient.

Double Deep Racking

Double Deep Racking is a special type of pallet racking. It has two opposite backs to save space for the aisle and sturdy omega pillar. Double Deep Racking have an average load of 2000 – 5000 kg/tier. Number of pallets containing goods from 4 to 10 pallets/tier.Specification of Double Deep heavy-duty rack:

- Suitable for forklift aisles from 3 to 3.4m

- Specialized forklift is required to operate

- Apply LIFO pick up method

Double deep racking are 2 rows of selective racking facing each other

Double Deep Racking are often used in warehouses with large loads such as electronic warehouses, industrial warehouses, agricultural product storage or cold storage.

Mold Rack

Mold racking are heavy-duty rack which store goods with large loads from 500kg to 2000kg/tier. Mold rack are easy to assemble and pick up because of the support sliding rails.

Specification of Mold rack:

- Made from high-strength steel and is powder-coated against rust to help preserve high-value products.

- Sliding trays for easy access to goods and pallets.

- The rack height can be raised and lowered easily because the beams assembled into the column by the hook bracket.

- The braces are designed with high strength to increase the load of the rack.

Mold rack with sliding trays for easier pick-up

Push Back Racking

The Push Back Rack has a rear push mechanism, when the packages are brought in later, they will push the package before it deep into the row. When taking a package out, the automatic mechanism of the shelf will push the package inside out to replace the position of the package just picked up. The load of the shelf is from 1000 – 2000 kg/floor corresponding to 2 – 4 pallets per row.Specification of Push Back Rack:

- Suitable for forklift aisles from 3 to 3.4m

- Apply LIFO pick up method

- The pallets will be pushed inward by the fork of the forklift

- Only use when the pallet is full of goods above

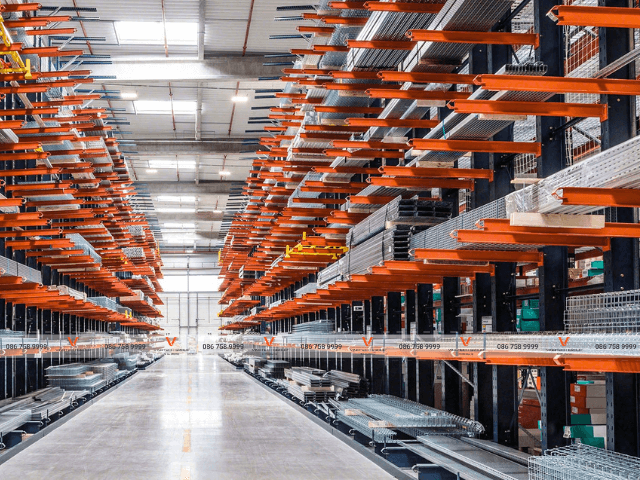

Cantilever Racks

Cantilever Racks are often used to store long and bulky goods and materials such as wooden bars, plastic pipes, steel pipes, carpets, furniture, cloth rolls… with heavy loads up to 3000 – 5000 kg/tier and more. This rack is suitable for storing items of different lengths on the same tier.

Cantilever Rack are very suitable for storage of fabric, steel

Mobile Rack

This is a system of rack that are close together, linked together and can be moved by sliding rails installed on the floor. The rack is moved together by electric motors controlled by humans or preset in automatic mode, which can be moved individually one by one. Mobile rack has a load capacity of 2000 – 3500 kg/tier.Features of Mobile rack:

- Suitable for forklift aisles from 3 to 3.4m

- Can be combined with selective racking systems to increased operational efficiency

- Suitable for cold storage

Mobile rack help import and export goods quickly and accurately

Mobile rack is suitable for warehouse systems that do not need to use multiple aisles, nor use forklifts or supporting equipment. This is a smart and modern warehouse system.

Drive in Rack

This rack is designed with rails, ensuring that the pallets are stacked side by side according to the depth of the support rails. Normally, each rack includes 6 to 8 tiers, each tier can hold from 4 to 12 pallets.Loading capacity from 1000 kg/pallet, this is the optimal type of heavy-duty racking for 70 – 80% of the warehouse area.

Specification of Drive-in Rack:

- Suitable for forklift aisles from 3 to 4.5 m

- Apply the FILO pick up method

- This rack can hold 10-12 pallets in depth and 6-7 pallets in height

- Optimal use of 70-80% of warehouse area.

Narrow Aisle Rack

Narrow Aisle racking is a heavy-duty rack with load from 3000 kg per tier. Although the load is very large but the height is not limited, it can be up to 18 – 20 m.

Specification of Narrow Aisle Rack:

- Suitable for forklift aisles from 1.8 to 2.2 m

- With structure and operation based on selective racking

- There is only 1 forklift in the aisle each time of importing and exporting goods

- Forklifts will pick up and store pallets from pick stations and then return them at the end of each rack compartment