- The mobile racking system movable takes about 30 seconds.

- Height of level from 1200 ÷ 4500mm.

- Input Power: 220V

- PLC control system

- Smart space management involves avoiding structure.

- Enable to Fix the mobile racking system, allows to operate exactly and quickly.

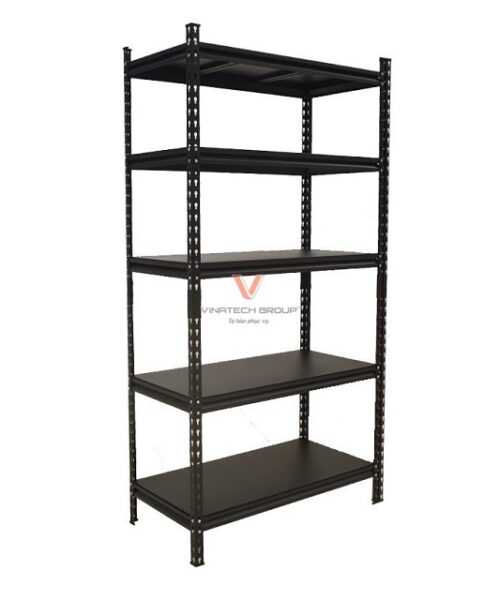

STANDARD SPECIFICATIONS

| Pallet (mm) | 800 x 1200 | 1000 x 1200 | 1200 x 1000 |

| Aisles (mm) | 800 | 1000 | 1200 |

| Beam Standard | 2700 | 2300 | 2700 |

| Level | 3 | 2 | 3 |

These criterias are in compliance with the Japanese safety standards which has been certified and widely applied in the rack/ shelf manufacture industry today. Based on this standard, Vinatech Group accurately measures system data to assure the product quality gain with ISO 9001: 2008 quality standard.

In the purpose of creating the best quality shelf products to ensure quality and safety criterias as well as meeting the Customer demands and archiving the customer’s storage system.

PRODUCT CHARACTERISTICS

Storage Method

- Mobile racking system are constructed by a series of selective rack.

- The foot pad is mounted with PLC control drive system.

- Support to inventory management more efficiently and easily.

- Save space for aisles as well as warehouse area is expanded significantly.

Mobile racking system save 50% space in a smart way

- Mobile pallet racking consists of First – End bay of racks system.

- The connector of two First-End bay of racks by Serial Mobile Racks.

- Mobile racking system only needs a single aisle for each system.

- Enable to create the aisle to approach the rack in use.

- When the palletization progress completed, a warehouse management can close the entire door to extend the warehouse area by 50%.

Aisles open mode (maximum width)

- The forklift can approaches the aisle quickly.

- Combination of rails and 3-way rotary forklifts or forklifts with a stand for shippers.

- Optimize the aisle width.

- The aisles has assembled wit full opening mode which can be opened on any bay in the system to help the forklift moving easily and saving time.

Aisles with half-open mode (convenience to manual palletization)

- In half-open mode, workers can approach the pallet in use to arrange the inventory cargo easily.

- Instead of arranging goods from one side, the mobile racking system could allow opening on both side at first-end point to dismantle and arrange goods quickly.

- Help to smart inventory management with high advantage of aisles open mode.

- Can open in any bay.

Dilatation mode to create the airy space

- Dilatation mode in order to support the loading/ unloading progress.

- Savings on air conditioning in frozen warehouse as it provides relative space between stored items and allows cold air to flow evenly.

- Dilatation mode will protect stored goods, especially frozen goods safety.