What Is the Two-Way Shuttle Rack System?

The Two-Way Shuttle Rack System is a semi-automated storage solution designed to optimize warehouse space and boost operational efficiency. Using robotic shuttles that move in both directions on rails, this system increases storage density by up to 80%, doubles handling speed, and cuts labor costs by up to 50% compared to traditional Drive-in racks. It’s the ideal solution for businesses upgrading from manual warehouses to automation at a reasonable investment level.

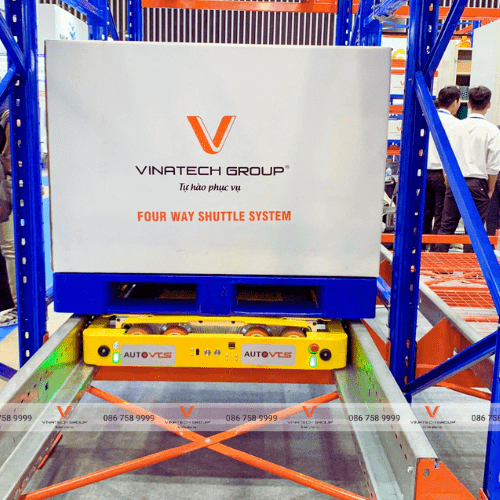

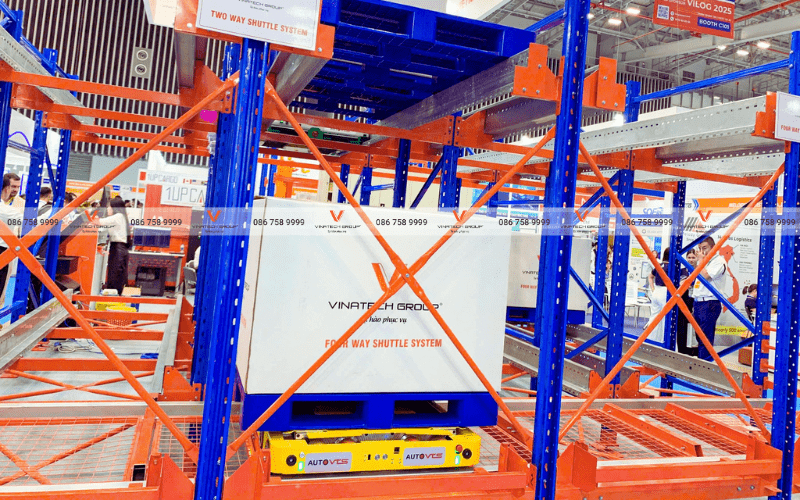

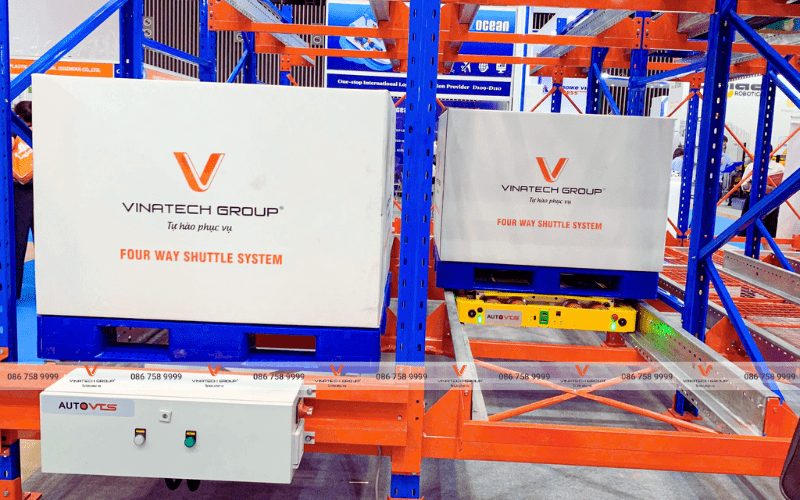

Developed by Vinatech Group, the Two-Way Shuttle Rack System combines three core components:

- Specialized racking structure

- Two-way shuttle robots

- Central control system (PLC controller)

Unlike conventional systems that require forklifts to enter the rack lanes, shuttle robots automatically transport pallets along rails, allowing forklifts to work only at the rack front. Each shuttle operates at speeds up to 1.2 m/s (unloaded) and 1.0 m/s (loaded), handling pallet weights from 500 to 1,200 kg.

System Structure & Operation

Key Components:

- Steel racking frame with adjustable base plates and guide rails

- ATS2 Series Shuttle Robots powered by 48V lithium batteries for 7–8 hours of continuous operation

Siemens S7-1200 PLC controller with PROFINET communication ensuring accuracy and reliability

Operation Process (5 Steps):

- Loading: Forklift places pallets at the rack entry point.

- Automatic transfer: Shuttle moves the pallet to the designated position.

- Placement: The shuttle lifts and sets the pallet precisely on the guide rails.

- Auto charging: When the battery is low, the shuttle returns to the charging station.

- Retrieval: System retrieves pallets using FIFO or LIFO principles.

Key Advantages

1. Space Optimization

- Increases storage density by up to 80% compared to selective racks.

- Eliminates forklift aisles, maximizing every cubic meter of warehouse space.

2. Speed & Productivity

- Up to 3× faster loading/unloading than Drive-in racks.

Multiple shuttles can work simultaneously on different levels.

3. Cost Efficiency

- Reduces labor needs by 40–50%.

- Decreases forklift wear and maintenance costs.

4. Safety & Accuracy

- Minimizes collision risk between forklifts and racks.

- Built-in obstacle sensors ensure safe operation.

- Automated pallet handling reduces product damage.

Comparison with Other Racking Systems

| Criteria | Two-Way Shuttle | Drive-In Rack | Selective Rack | Four-Way Shuttle |

| Storage Density | 80% | 70% | 40–50% | 85–90% |

| Speed | High | Low | Medium | Very High |

| Investment Cost | Medium | Low | Low | High |

| Automation Level | Semi-auto | Manual | Manual | Fully Auto |

| Safety | High | Medium | Medium | Very High |

| FIFO/LIFO | Both | LIFO only | Both | Both |

Best Fit for

- Manufacturing plants (food, beverage, chemical industries) with high-volume batches.

- Logistics & distribution centers aiming to semi-automate warehouse operations.

- Companies transitioning from manual to automated systems with mid-level budgets.

- Warehouses with 50–500 SKUs, requiring flexible FIFO/LIFO management.

When Not Ideal

- Small warehouses with low pallet turnover.

Large-scale facilities with complex SKU structures (should consider Four-Way Shuttle or ASRS). - Businesses with very limited budgets.

Why Choose Vinatech Group?

- International-standard technology: Siemens PLCs, high-quality brushless motors, and durable steel structures.

- Team of expert engineers: Vinatech Group has a team with more than 10 years of experience in designing and implementing warehouse automation.

- Professional installation & after-sales service: Full technical documentation, operator training, and 24/7 support.

- Trusted by top brands: Vinamilk, PepsiCo, Nestlé, CJ Foods, and over 500 leading companies in Vietnam.

Vinatech Group – Vietnam’s Leading Warehouse Storage Solution Provider

Head Offices:

- Hanoi: 15th Floor, TTC Building, 19 Duy Tan, Cau Giay, Hanoi

- Da Nang: 219–223 Pham Hung, Hoa Xuan, Cam Le, Da Nang

- Ho Chi Minh City: Lot C2-7, N7 Street, Tan Phu Trung Industrial Park, Cu Chi District