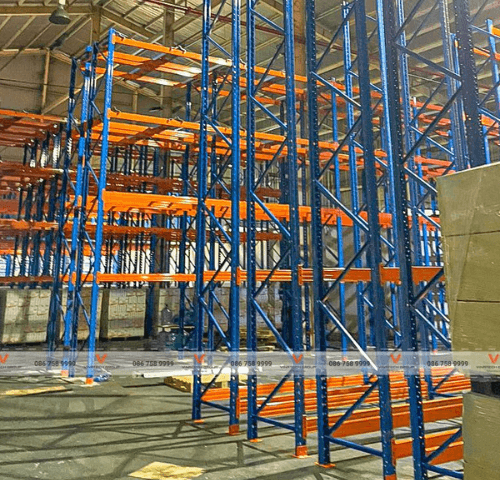

Double Deep Pallet Racking is an upgraded variant of Selective Racking, designed by pairing two Selective racking rows back-to-back, creating double-depth rack lanes. This solution increases storage density by up to 30-40% compared to traditional Selective racking, while maintaining reasonable investment costs and high durability.

At Vinatech Group – Vietnam’s leading reputable warehouse racking manufacturer – we provide high-quality Double Deep Racking, made from standard steel with electrostatic powder coating for rust resistance. The system is custom-designed according to your business’s load requirements and warehouse space.

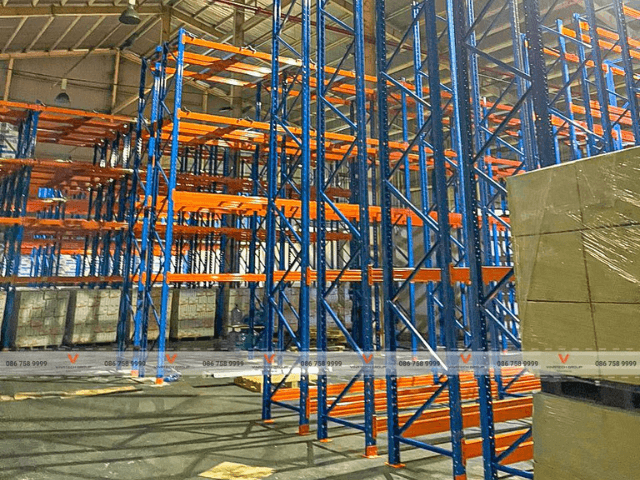

Structure of Double Deep Racking

The structure of Double Deep Racking is similar to Selective Racking but optimized for double depth, ensuring robustness and operational safety:

- Upright frames: Primary load-bearing components, robust Omega profile, premium steel thickness, featuring multiple punched holes for flexible beam level adjustment.

- Beams: Connect between upright frames, directly support pallets, secured with anti-fall safety clips.

- Bracing: Horizontal and diagonal braces link the uprights, enhancing overall system stability for deep rack lanes.

Pallet support bars or guide rails: Placed on beams to ensure stable pallet movement and prevent misalignment during loading/unloading with forklifts.

Column protectors and safety barriers: Installed at rack bases, aisle ends, and high-risk impact zones to protect frames from forklift collisions.

The entire system uses modular bolted assembly, making it easy to expand, adjust, and maintain.

Advantages and Disadvantages of Double Deep Racking

Advantages:

- Increases storage density by 30-40% compared to Selective Racking, reduces the number of aisles, and optimizes warehouse space.

- Cost per pallet position is more economical than fully automated systems (Flow Rack, Drive-in, etc.).

- Robust structure with excellent heavy-load performance, suitable for high-capacity warehouses.

- Easy installation, beam adjustment, and future expansion.

Disadvantages:

- Pallet accessibility is only about 50% (outer pallets must be removed first to reach inner ones).

- Requires specialized Reach Trucks, resulting in higher equipment investment costs.

- Not suitable for short-shelf-life goods or strict FIFO requirements.

- Demands precise operating procedures to avoid blockages or collisions.

Applications

- Double Deep Racking is particularly suitable for warehouses needing high storage density while keeping costs under control:

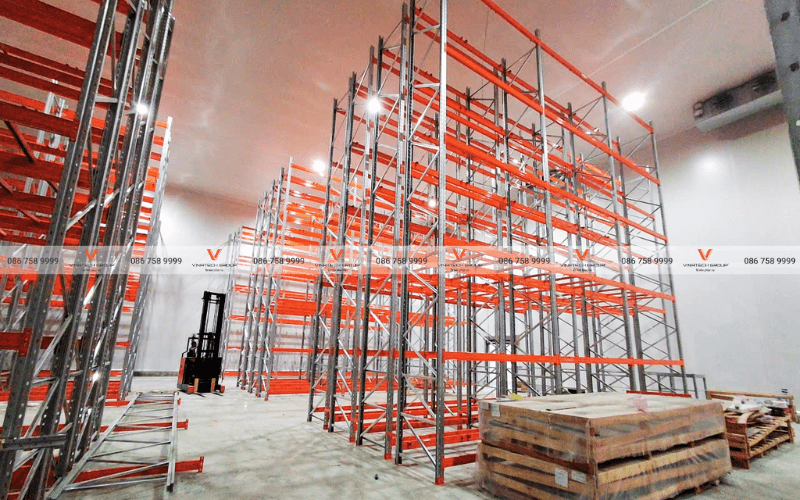

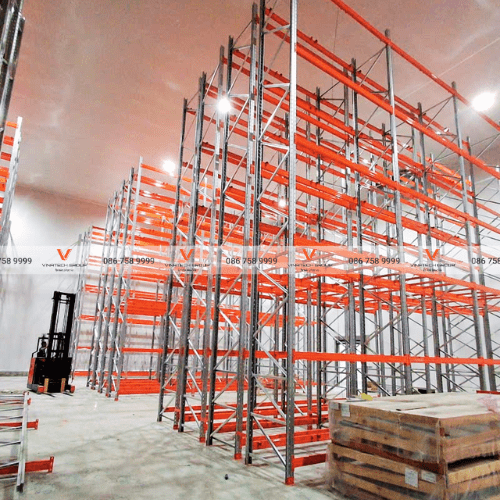

- Cold storage and chilled warehouses: Optimizes refrigeration capacity by reducing aisles and increasing pallets per area – top choice for food, seafood, and pharmaceutical cold storage.

- Heavy industrial warehouses: Storage of large-volume, uniform components and production raw materials.

- Fast-Moving Consumer Goods (FMCG): Ideal for high-volume, low-SKU batches with longer shelf life.

- Paper and packaging warehouses: Storage of large identical paper rolls or packaging bundles, compact and space-efficient.

- Electronic component distribution warehouses: Storing spare parts or pre-assembly products in large pallet quantities per SKU.

Are you looking for a Double Deep Racking solution to optimize cold storage or industrial warehouse space? Contact Vinatech Group right away for a free site survey, detailed 3D design, storage density calculations, and the best 2026 pricing!

Hotline: 086.758.9999 | Email: info@vinatechgroup.vn

Website: vinatechgroup.vn

We commit to custom manufacturing, export-quality standards, and professional nationwide installation.

Frequently Asked Questions

1. Is Double Deep Racking suitable for FIFO inventory management?

No, Vinatech Double Deep Racking operates on LIFO (Last In – First Out) principle – last in, first out. It is suitable for uniform goods with slow turnover.

2. Which forklift is best suited for Double Deep Racking?

The most suitable is a specialized Reach Truck with extendable forks (double deep reach truck), allowing deep pallet retrieval without excessively wide aisles, ensuring safety and efficiency.

3. How long does the Double Deep Racking installation process take?

For Vinatech Double Deep Racking, production takes 7–15 days and installation takes 5–10 days for an average warehouse (~1000 pallets).

4. Can Double Deep Racking be used in cold storage environments?

Yes, fully suitable! Vinatech Double Deep Racking uses anti-oxidation electrostatic powder coating, ideal for cold storage (food, pharmaceuticals), optimizing space and reducing operating costs.

5. What is the maximum real-world load capacity per level for Double Deep Racking?

The maximum load per level for Vinatech Double Deep Racking is 3,000 kg (or higher with heavy-duty custom design, including high safety factors).

6. Can Double Deep Racking be easily expanded when the warehouse grows?

Yes, Vinatech Double Deep Racking is modular (bolted design), allowing easy expansion, addition/removal of rows, and flexible reconfiguration as your warehouse scales – perfect for growing businesses.