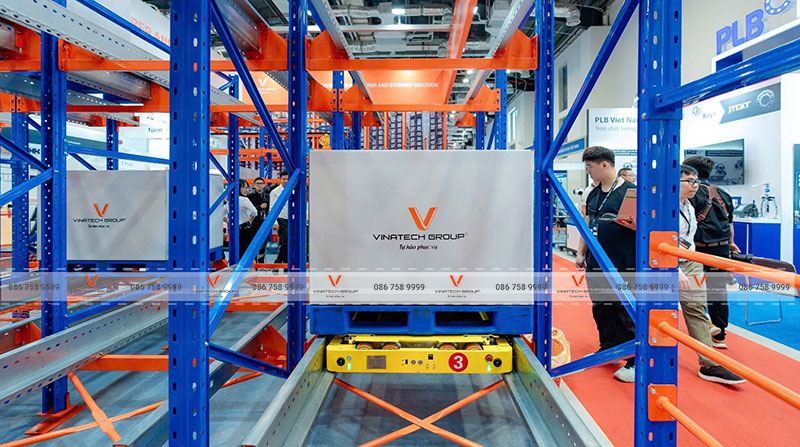

What Is a Four-Way Shuttle Rack System?

The Four-Way Shuttle Rack System is an advanced automated storage and retrieval system (ASRS) that integrates:

- Four-way shuttle robots

- Conveyor networks and vertical lifts

- Specialized high-density racks

- Smart warehouse management software (WMS/WCS/WES)

Unlike the Two-Way Shuttle system, the four-way shuttles can travel in all directions, allowing unrestricted pallet access, flexible layout design, and seamless warehouse expansion without structural changes.

Each shuttle operates at speeds up to 1.5 m/s (unloaded) and 1.2 m/s (loaded), handling loads between 500–1,500 kg per pallet, running 24/7 with real-time system coordination through Siemens PLC and Vinatech’s intelligent control software.

System Architecture

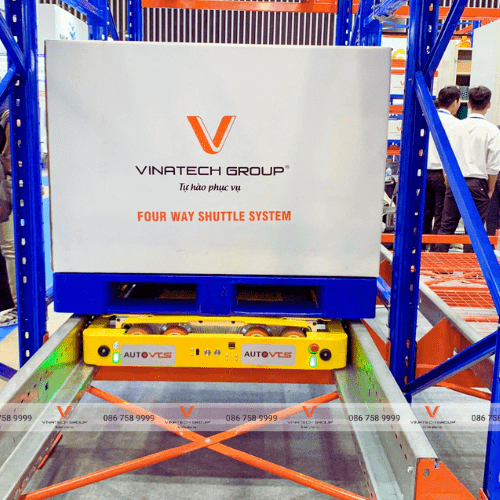

1. Four-Way Shuttle Robots

- Load capacity: 500–1,500 kg per pallet

- Speed: 1.5 m/s (unloaded), 1.2 m/s (loaded)

- Power: 48V lithium battery, 7–8 hours continuous operation

- Temperature range: 5°C–45°C (custom versions for cold storage)

- Movement: Full 4-direction travel for optimal route efficiency

- Communication: Wireless link with WMS/WCS for instant coordination

2. Conveyor System

Handles pallet flow between storage, lifts, and outbound zones.

Includes automatic check stations for:

- Weight verification

- Dimension scanning

- Barcode/QR code reading

- Auto-reject for out-of-spec goods

3. Lift System

Vertical lifts transport shuttles and pallets between rack levels.

- Speed: 0.5–1 m/s

- Precision: ±2 mm

- 24/7 continuous operation with smart task scheduling

4. Warehouse Software Suite

- WMS (Warehouse Management System): Oversees inventory, storage positions, and order processing.

- WES (Warehouse Execution System): Coordinates real-time task distribution and load balancing.

- WCS (Warehouse Control System): Directly controls hardware—shuttles, conveyors, and lifts—for accurate execution.

Automated Workflow (6 Steps)

- Receiving: Pallets enter via forklifts, AGVs, or AMRs. The system automatically checks weight, dimensions, and barcode data.

- Lifting: The vertical lift moves pallets to designated rack levels.

- Shuttle Transfer: The four-way shuttle receives instructions from WCS and travels directly to the assigned storage location.

- Storage: The shuttle lifts, places, and records pallet data in WMS in real time.

- Retrieval: Upon order request, the shuttle retrieves the correct pallet and transfers it to the conveyor for dispatch.

- Auto-Charging: When the battery runs low, the shuttle autonomously returns to a charging dock without human intervention.

Core Advantages

1. Maximum Space Utilization

- 85–90% storage density, eliminating forklift aisles.

- Optimized for both horizontal and vertical expansion.

2. Superior Efficiency

- 5–7× faster throughput than manual operations.

- Intelligent AI routing minimizes travel distance and waiting time.

3. Fully Automated Operation

- Reduces labor costs by up to 80%.

- Continuous 24/7 unmanned operation with minimal downtime.

- Error rate <0.1% through automated inspection and barcode tracking.

4. Flexible & Scalable

- Add more shuttles as demand grows without layout changes.

- Supports multi-level, large-scale warehouses and cold storage environments.

5. Safety & Accuracy

- No forklifts or workers inside storage aisles → zero collision risk.

- Real-time inventory visibility and traceable pallet movement.

- Seamless integration with ERP/SAP and IoT systems.

Comparison with Other Systems

| Criteria | Four-Way Shuttle | Two-Way Shuttle | ASRS | Drive-in Rack |

| Storage Density | 85–90% | 80% | 90–95% | 70% |

| Throughput Speed | Very High | High | Very High | Low |

| Investment Cost | High | Medium | Very High | Low |

| Automation Level | Fully Auto | Semi-Auto | Fully Auto | Manual |

| Scalability | Excellent | Good | Average | Poor |

| ROI | 3–5 years | 2–4 years | 5–7 years | N/A |

| OPEX | Very Low | Low | Very Low | High |

Ideal Applications

- National distribution centers (e-commerce, FMCG, logistics hubs).

- Large-scale manufacturing (automotive, electronics, pharmaceuticals).

- Cold storage facilities (seafood, frozen food, cold logistics).

- 3PL/4PL providers requiring ultra-fast, high-accuracy operations.

- Digital transformation projects integrating WMS/ERP/IoT ecosystems.

Why Choose Vinatech Group?

✅ World-class technology: Components from Siemens, Schneider, and top automation partners.

✅ Proven expertise: 10+ years in smart warehousing, serving Vinamilk, Nestlé, Unilever, Maersk, DHL and others.

✅ Custom engineering: Tailored 3D simulations, ROI calculations, and optimized warehouse layouts.

✅ Full turnkey solutions: Design → Equipment → Software → Installation → Training → After-sales support.

✅ Long-term reliability: 24/7 technical service, preventive maintenance, and uptime >98%.

Vinatech Group – Vietnam’s Leading Warehouse Storage Solution Provider

Head Offices:

- Hanoi: 15th Floor, TTC Building, 19 Duy Tan, Cau Giay, Hanoi

- Da Nang: 219–223 Pham Hung, Hoa Xuan, Cam Le, Da Nang

- Ho Chi Minh City: Lot C2-7, N7 Street, Tan Phu Trung Industrial Park, Cu Chi District