What is Automated Warehouse?

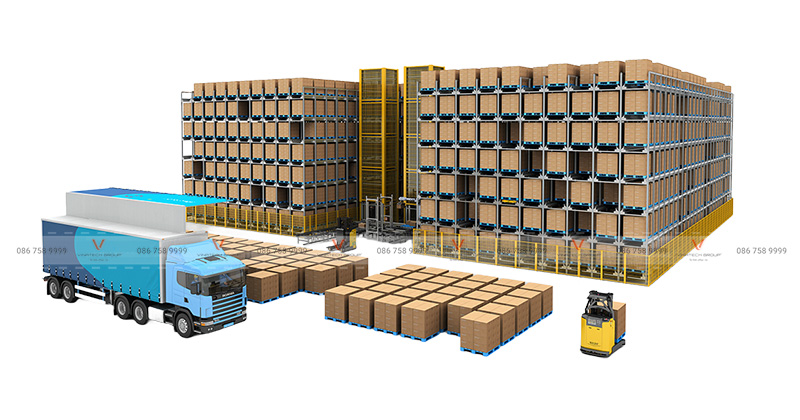

An automated warehouse is a system utilizing machinery and equipment to store and handle goods autonomously through conveyors, robots, and warehouse management software for receiving, storage, and material transport operations.

System Categories

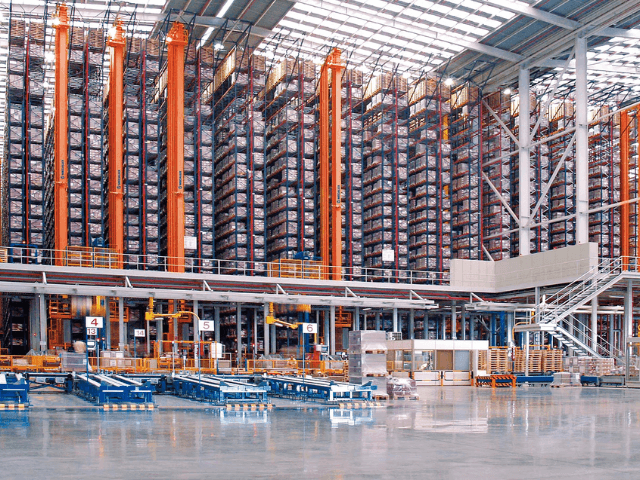

- Vertical Automation: High-bay storage systems using computer-controlled vertical racking for automated inbound/outbound operations.

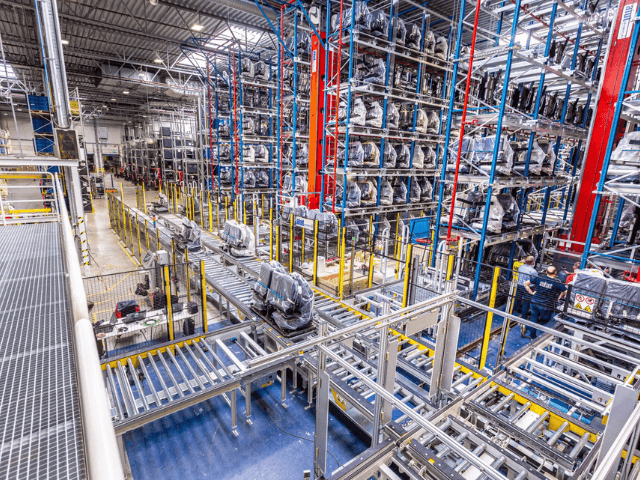

- Horizontal Automation: Conveyor-based systems enabling automated lateral goods movement between warehouse locations.

- Hybrid Systems: Integrated vertical and horizontal automation delivering optimal performance.

Operational Benefits

- Space Efficiency: Maximizes vertical capacity for high-density pallet storage while maintaining safety standards, significantly exceeding traditional warehouse capacity.

- Performance Gains: Delivers up to 50% operational efficiency improvement through automated task execution, reducing time and costs.

- Labor Optimization: Operates via automated production lines where finished goods transfer to storage through conveyors and robots. Storage locations are system-predetermined based on stored data, requiring only one operator versus traditional multi-person operations.

- Cost Reduction: Achieves up to 30% warehouse operating cost savings through automated processes minimizing labor requirements.

- Service Quality: Improves customer service quality by 20% through automated order fulfillment ensuring speed and accuracy.

- Precision Control: Each storage location has a unique IP address containing encoded product data (manufacturing date, receipt date, quantity, SKU, etc.). The system identifies goods locations via IP addressing and automatically retrieves items using conveyors, picking robots, and cranes.

- Flexible Software: Programmable for diverse products and customer requirements, accommodating various storage regulations and conditions for effective management without control concerns.

- Modular Construction: Smart warehouse systems feature modular design enabling easy installation, relocation, repair, and replacement without disrupting overall operations.

Operational Workflow

Computer systems control all warehouse operations including receiving, storage, picking, and shipping. Sensors identify goods locations and direct equipment accordingly.

- Receiving: Staff scan barcodes upon arrival; the system identifies storage locations and directs equipment to transport goods.

- Storage: System updates inventory positions in WMS, providing retrieval information when needed.

- Picking: Staff access WMS to locate goods; system controls equipment to move items to shipping zones.

- Shipping: Staff package and dispatch goods from shipping areas.

Implementation Requirements

Digital Technology Investment:

- Industrial smartphones and tablets

- Wireless barcode scanners

- Software and internet networks

- Cloud databases

- Machine learning algorithms

- Data analytics platforms

Digital automation eliminates manual order tracking and human error while enabling proactive data retrieval, ensuring accurate and timely order fulfillment while reducing staffing needs.

Barcode, Label & RFID Deployment:

Technology deployment enables automated, accurate, convenient, and real-time warehouse management. Managers gain detailed visibility into object locations, actual inventory quantities, and continuous inbound/outbound data, optimizing efficiency and costs.

Key objectives:

- UHF RFID smart tags manage product movements and quantities, supporting inventory counts and actual stock statistics

- Enables fast data queries, reporting, and information sharing with relevant individuals and organizations

Robotic Integration:

Warehouse robots handle tasks including AGV transport, loading/unloading, pallet handling, product/shelf movement, and pick-and-place operations within conveyor systems.

Modern warehouse robots feature embedded computers, AI, machine learning, and internet integration. AI-powered systems efficiently sort packages, boosting productivity, increasing revenue, and accelerating ROI.

Robots improve warehouse efficiency for repetitive tasks like sorting and order picking. Picking can represent 50%+ of warehouse labor costs, especially in large facilities. Automated sorting and picking systems reduce labor costs and workplace injuries, allowing staff to focus on complex processes like inventory management, order fulfillment, and delivery.

Vendor Selection Criteria

- Experience: Established automation providers offer extensive knowledge of system types, ensuring suitable enterprise solutions.

- Product Range: Diverse automated warehouse systems and services provide options matching business requirements.

- Competitive Pricing: Cost-effective vendors reduce automation investment expenses.

- Warranty Programs: Strong warranty coverage ensures system quality confidence.

- Customer References: Previous client feedback reveals service and product quality insights.

Vinatech Group: Trusted Automation Partner

With 14+ years of experience, Vinatech Group ranks among Vietnam’s most reputable automated warehouse solution providers. Our professional technical team delivers expert consultation and installation tailored to business needs and budgets, backed by comprehensive warranty programs.

Frequently Asked Questions

Is automated warehousing suitable for all businesses? Automated warehouses suit diverse enterprises from small to large, requiring thorough analysis of needs and investment capacity.

What are implementation timelines? Deployment depends on scale and specific requirements. From design through integration, testing, and launch, timelines range from several months to one year based on project complexity.

What are deployment and operating costs? Costs depend on factors including scale, technology, and specific requirements, encompassing installation, materials, labor, and maintenance expenses.

Can management systems integrate with warehouse automation? Automated warehouse systems typically integrate with warehouse management systems and operational processes through standard protocols and software.

Vinatech Group – Leading manufacturer and provider of warehouse racking and smart storage solutions in Vietnam

Contact: +84 86 758 9999 | info@vinatechgroup.vn | vinatechgroup.vn

Offices:

- Hanoi: 15th Floor, TTC Building, 19 Duy Tan Street, Dich Vong, Cau Giay

- Da Nang: 219-223 Pham Hung Street, Hoa Xuan, Cam Le

- Ho Chi Minh City: Lot C2-7, N7 Road, Tan Phu Trung Industrial Park, Cu Chi District