Smart warehouse racking integrate automated technology and warehouse management software (WMS) to optimize inventory storage, retrieval, and management operations. Unlike traditional static racks, smart racking employs robots, conveyors, and IoT sensors for near-autonomous operation—boosting productivity, reducing labor costs and errors, while maximizing vertical storage capacity. join Vinatech Group to explore pricing information!

1. What Defines a Smart Warehouse Racking?

Smart warehouse racks are modular steel storage structures with contemporary engineering, assembled using bolts and fasteners for easy reconfiguration, disassembly, and relocation. Multi-tier designs enable systematic organization of goods, streamlining inventory control and operational workflows.

Key characteristics:

- Exceptional durability: 20+ year service life with high load-bearing capacity and impact resistance

- Safety-first design: Protects both inventory and warehouse personnel

- Versatile load capacity: Accommodates heavy-duty, medium-duty, and light-duty storage requirements

- Wide application scope: Food storage, cold rooms, pharmaceuticals, electronics components, chemicals, footwear, document archives, raw materials, paint, textiles, and more

2. Leading Smart Racking Technologies for Modern Warehouses

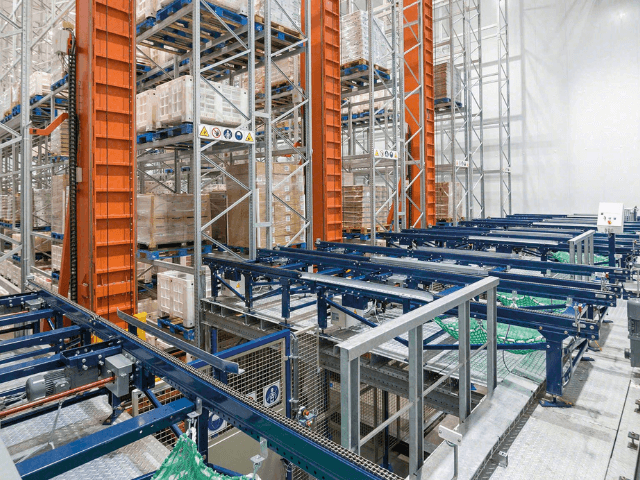

2.1. ASRS (Automated Storage and Retrieval System)

ASRS represents the most widely deployed smart racking solution on the market. This fully automated system handles storage, retrieval, and inventory management with minimal human intervention, delivering rapid, precise, and efficient warehouse optimization.

The warehouse racking system leverages autonomous robots, vertical lifts, conveyor belts, and specialized management software to execute all inbound/outbound operations, retrieval tasks, and goods arrangement on-demand without manual handling.

Core advantages:

✅ Maximized storage density: High-density storage eliminates excessive aisles, fully exploits vertical height

✅ Rapid, accurate retrieval: Meets real-time packing and shipping demands while minimizing errors

✅ Comprehensive automation: Reduces workforce requirements, cuts operational costs, limits workplace accidents

✅ Strict inventory control: Software provides access management and real-time stock monitoring

✅ High SKU capacity over large footprints: Ideal for facilities 10,000m² and above, e-commerce companies, tech firms

✅ Performance optimization: Robots replace traditional forklifts, accelerating throughput and inventory turnover

✅ Flexible configurations: Adapts to warehouse layouts, can integrate automated conveyors from receiving to packing zones

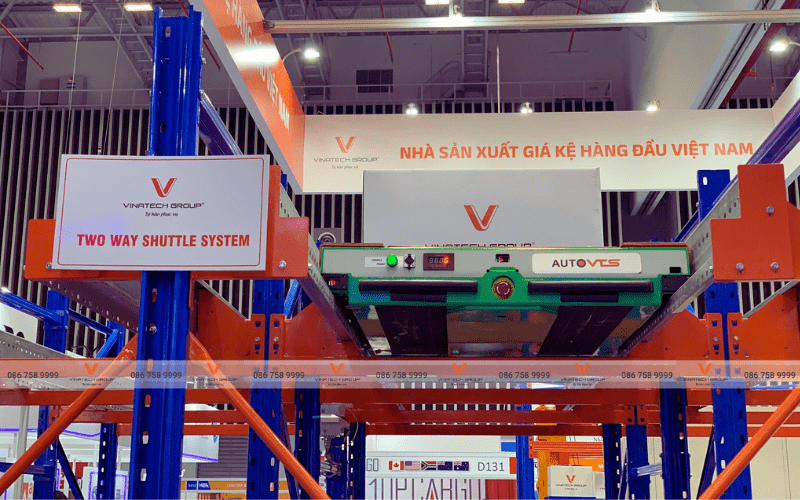

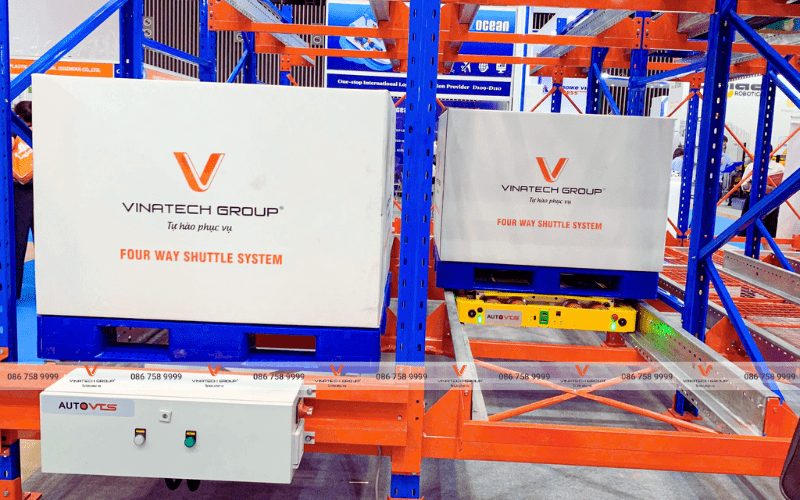

2.2. Shuttle Racking Systems (Radio Shuttle Rack)

Shuttle racking employs automated shuttle robots running on rails to transfer pallets within the rack structure, controlled via remote or computer interface. This smart storage solution keeps forklifts outside the rack, reducing cycle times, preventing collisions, and tripling storage capacity versus conventional systems.

Primary benefits:

✅ Superior space utilization: Extremely high storage density, utilizing 80% of warehouse floor area, rack depth can reach 40m or more

✅ Accelerated throughput: Shuttle robots travel at 0.8–1.2 m/s, enabling fast loading/unloading, reducing wait times, increasing warehouse productivity

✅ Reduced labor and operating costs: Automated operation, forklifts remain outside racks, minimizing collisions and damage risks

✅ FIFO & LIFO flexibility: Accommodates diverse inventory management requirements, optimizing goods rotation processes

✅ Stable operation, energy efficient: Lithium battery-powered shuttles run continuously 5–8 hours, rapid recharge, low power consumption

✅ Cold storage & heavy-duty capable: Functions efficiently at temperatures down to -25°C, maximum load 1500kg/pallet

✅ Precise retrieval: Automatic sensors identify pallet positions, reducing operational errors

✅ Scalable expansion: Robot quantity increases as throughput demands grow, suitable for e-commerce, food, logistics, heavy industry warehouses

2.3. Mobile Shelving (Manual Crank System)

Mobile shelving is a movable smart storage system enabling secure storage and space optimization through manual or automated movement along floor rails via hand crank mechanism.

Commonly deployed in libraries, museums, office document archives, and vaccine cold storage facilities.

Notable advantages:

✅ 45% space savings compared to static shelving, utilizing 90% of warehouse floor area

✅ Enhanced security: Lockable units suitable for confidential files, sensitive documents, high-value inventory

✅ Easy access: Quick retrieval, inventory counting via single aisle access

✅ Smooth operation: Minimal labor and operational expenditure

✅ Professional aesthetics: Appropriate for both office and warehouse environments

✅ Modular flexibility: Easy expansion as storage needs increase

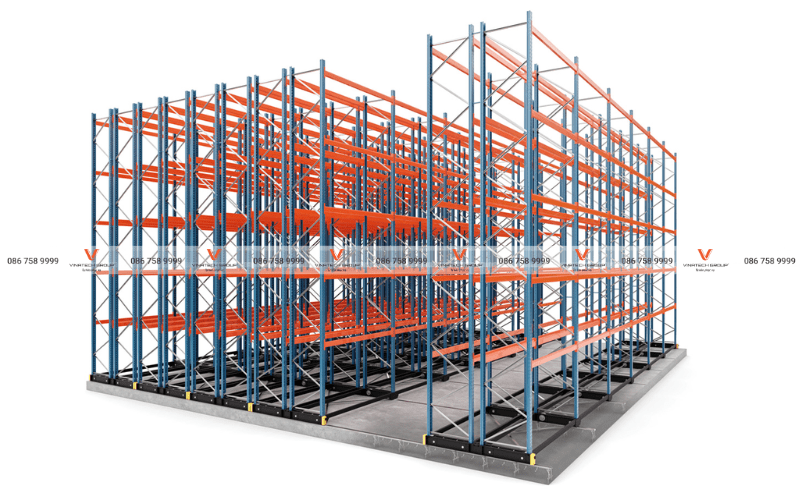

2.4. Mobile Racking (Motorized Mobile Racking)

Mobile rack systems utilize rail tracks combined with electric motors to move racks across the floor, optimizing storage space up to 90%—ideal for freezer storage, compact facilities, or operations requiring flexible inventory access.

Mobile racks can shift individual rows or entire systems effortlessly through modern PLC control systems, ensuring 100% pallet accessibility with rapid, safe retrieval while minimizing collision risks.

Strategic advantages:

✅ 50% warehouse space reduction, optimized aisle configuration, increased storage density

✅ 100% inventory accessibility at all positions, simplified retrieval

✅ Automation-ready: Reduces workforce, accelerates inbound/outbound velocity

✅ Energy savings for cold storage through uniform air circulation

✅ Seamless integration with automated forklift or AGV systems

✅ Heavy-duty inventory: Perfect for goods requiring strict management protocols

3. Expert Consultation and Custom Solutions

For professional consultation and detailed quotations on smart warehouse racking systems, contact Vinatech Group at Hotline: 086.758.9999. With over 12 years of experience in Vietnam’s warehouse storage market, we deliver customized solutions for racking models, load capacities, colors, and specifications.

4. Vinatech Group’s Competitive Advantages

Manufacturing excellence:

- Two large-scale production facilities in Hanoi and Ho Chi Minh City

- Annual production capacity: 15,000 tons

- Full supply capability for domestic and international export markets

Premium materials and technology:

- Grade 1 cold-rolled steel and premium powder coating for quality and aesthetics

- Advanced surface treatment with electrostatic powder coating for brilliant, uniform finish and extended product lifespan

- State-of-the-art equipment: Automated welding robots, punching machines, roll forming machines, CNC laser cutting systems

Professional expertise:

- Highly skilled technical engineering team with extensive experience

- ISO 9001 and AS 4084-2023 certified racking products

- ISO 45001:2018 and ISO 14001:2015 certified operations

All Vinatech-branded smart racking systems meet premium quality standards. Our highly trained engineers and skilled workforce follow international ISO 9001:2015 quality management protocols.

Vinatech Group — Leading manufacturer and provider of warehouse racking and smart storage solutions in Vietnam

📞 Hotline: 086.758.9999

📧 Email: info@vinatechgroup.vn

🌐 Website: vinatechgroup.vn

Office locations:

- Hanoi: 15th Floor, TTC Building, 19 Duy Tan Street, Dich Vong, Cau Giay District

- Da Nang: 219-223 Pham Hung Street, Hoa Xuan, Cam Le District

- Ho Chi Minh City: Lot C2-7, N7 Road, Tan Phu Trung Industrial Park, Cu Chi District