Mechanical Warehouse Racking is a product line used for storing materials and tools that is attracting considerable attention. Using these professional warehouse storage shelving systems creates scientific, modern storage spaces while saving storage area for businesses. Join Vinatech Group to explore the most suitable mechanical warehouse racking types for manufacturing workshops and parts facilities, the remarkable benefits they provide, and secrets to selecting the optimal shelving for your requirements.

What is Mechanical Warehouse Racking?

Mechanical warehouse racking refers to cabinets, bags, boxes, containers, and tool storage shelves… that function as organizing and storing specialized equipment, various wrenches, hammers, drills, screws, etc., commonly used in professional mechanical manufacturing and repair facilities, electricians, plumbers, and auto mechanics.

When using mechanical warehouse storage racking, workers can confidently use equipment, and tools will be arranged neatly and orderly to avoid situations where tools and equipment are scattered haphazardly, causing confusion and mix-ups.

Mechanical Warehouse Racking helps organize and neatly arrange mechanical tools

8+ Most Popular Types of Mechanical Warehouse Racking Today

The current market offers many different types of mechanical industry warehouse storage racking, with the following popular models:

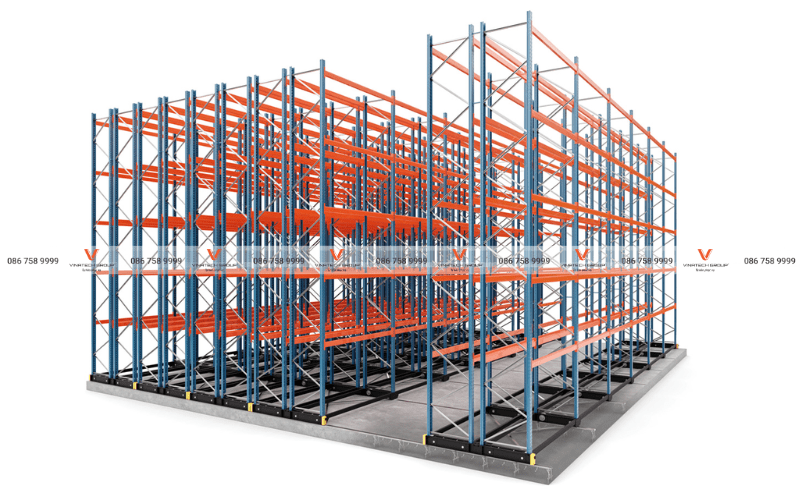

Automated Shuttle Mechanical Racking

Shuttle is a remote-controlled automated storage racking system using robots or shuttles running on rails to handle goods transfer and input/output instead of forklifts. With industrial racking solutions specifically designed for each mechanical industry sector.

Vinatech Group’s mechanical Shuttle racking ensures optimal application regarding space, costs, and operations, bringing speed and convenience to mechanical business warehouses.

Drive-In Mechanical Tool Storage Racking

This type of industrial warehouse racking has frame columns interconnected to create an extremely solid racking block. The system can optimize up to 90% of mechanical workshop warehouse area for storing mechanical tools when the pallet system contains uniform goods and is suitable for rails.

With Drive-in warehouse racking, forklifts must move deep into the rack rows, stacking goods from inside to outside and from low to high sequentially. Goods retrieval follows FIFO or LIFO methods.

Selective Mechanical Tool Storage Racking

Selective pallet Racking is currently the most popular type of mechanical goods storage racking. The shelving is designed to fit all pallet sizes, can accommodate all forklift types, with 90% goods accessibility capability.

This pallet rack model is very suitable for industrial warehouses with many varieties, multiple pallet types, and no need for excessive storage area optimization.

Double Deep Mechanical Industry Storage Racking

Double Deep racking is a shelving type with a structure of two double Selective rack rows placed back-to-back, with goods accessibility at 50% compared to Selective racking. This approach aims to reduce forklift aisle space and limit goods retrieval by 50% in mechanical warehouses.

Mobile Warehouse Racking for Mechanical Tools

The mechanical warehouse storage racking system includes closely spaced pallets, support racks that are interconnected and can move back and forth on rails installed on the floor using electric motor controls while providing forklift access.

Mobile warehouse racking is commonly used in modern mechanical warehouses. They both optimize warehouse storage area by 70%-80% while accessing 100% of goods with load capacity of several tons per tier.

Mezzanine Flooring for Mechanical Warehouses

Industrial mezzanine flooring serves to increase usable area without expanding warehouse floor space. The higher the mechanical factory, the easier it is to design multiple storage levels using flooring. The advantage of this shelving is increasing empty space for storage by 200%-300%, storing large quantities of goods.

Steel Shelving for Mechanical Tools

Multipurpose steel shelving models used for mechanical warehouses are assembled from premium V-shaped steel bars. Shelving is interconnected using bolt and screw systems providing absolutely safe storage capability for users.

Shelving is commonly used in warehouses and stores with small scale and area. However, dimensions also depend on the wave barriers under steel panels.

Mechanical Tool Hanging Racks

Mechanical tool hanging racks or Pegboard hanging boards are equipment that helps organize storage and smart display, neat and easy to find repair tools when needed.

The shelving has a special separate design used for hanging tools such as: screwdrivers, pliers, scissors, hammers, drills, cutting machines, ladders, bicycles… Tool hanging hooks can be flexibly assembled/disassembled and storage positions of tools can be changed.

Latest 2025 Authentic Mechanical Warehouse Racking Pricing

Mechanical warehouse racking has market prices ranging from 686,000 VND for one complete racking set. Shelving prices depend on dimensions, height, and thickness of tier panels.

At Vinatech Group, installation prices for optimizing storage space provide the highest investment efficiency for businesses. Customers installing at Vinatech Group receive:

✅ Free 2D, 3D design suitable for warehouse requirements

✅ Direct installation from manufacturer – no intermediaries, cost savings

✅ Modern automation solutions help optimize space, increase input/output speed

📞 Contact 086.758.9999 via Hotline immediately for detailed consultation on mechanical warehouse racking solutions!

Quality Mechanical Warehouse Racking Installation Addresses with Good Load Capacity

With 14 years of experience, Vinatech Group provides heavy-duty warehouse racking installation solutions optimizing costs. Vinatech Group advantages:

✅ Two modern factories in the North and South, total area 50,000 m²

✅ Extensive distribution network, over 200 dealers nationwide

✅ Team of 500 experienced personnel, always ready for professional consultation, installation, and warranty services

✅ Over 50,000+ successful projects, serving diverse industries and business models

✅ Closed production line meeting ISO 9001:2015 standards, applying modern technology

✅ Trusted partner of major brands: Streamax, FPT, Honda, Lazada, Shopee, ITL, EVN Power, LG,…

Contact Vinatech Group immediately for direct consultation with customers needing professional and most suitable steps.

Above, Vinatech Group has introduced businesses to free mechanical warehouse racking installation experience. Or you can leave information below, we will contact you as soon as possible.

Vinatech Group is Vietnam’s leading manufacturer and provider of warehouse racking and smart warehouse solutions

Hotline: 086.758.9999

Email: info@vinatechgroup.vn

Website: vinatechgroup.vn

Office System:

- Hanoi: 15th Floor, TTC Building, No. 19 Duy Tan Street, Dich Vong, Cau Giay, Hanoi

- Da Nang: 219-223 Pham Hung Street, Hoa Xuan, Cam Le, Da Nang

- Ho Chi Minh City: Lot C2-7, N7 Road, Tan Phu Trung Industrial Park, Cu Chi District, Ho Chi Minh City