Material storage racking systems are widely used for storing supplies, components, and small items in professional warehouse facilities. These specialized racking solutions optimize storage space, facilitate easy access, and streamline inventory control for material warehouses. join Vinatech Group to explore pricing information!

What Is Material Storage Racking?

Material storage racking refers to warehouse shelving systems designed to store and organize supplies, components, or goods in warehouses and factories. These racks are engineered to optimize storage space, making inventory management and retrieval more convenient.

Material racking can be classified into various types including medium-duty racking, selective racking, or V-slot racking, depending on storage requirements and material load capacity.

Vinatech Group specializes in designing and manufacturing internationally standardized racking with superior quality at reasonable prices. Our modern machinery systems and skilled workforce consistently deliver the best material storage racking solutions.

Types of Material Storage Racking by Load Capacity

V-Slot Steel Racking for Small Materials

V-slot steel racking (multi-purpose steel shelving) is the smallest warehouse material storage solution currently available. This affordable steel racking features modular assembly design, making disassembly and relocation extremely easy. Load capacity: <100 kg/level.

With V-slot modular steel racking, customers can independently disassemble, relocate, and adjust positions as well as spacing between levels according to specific needs. Consequently, this product enjoys strong market popularity.

Light-duty material racking suits warehouses storing medium and light loads from 70-100 kg/level, providing optimal space solutions that maximize storage capacity within the same warehouse footprint.

Medium-Duty Material Shelving

Currently, the market offers various Medium-duty Shelving models suitable for different usage requirements. The three most popular models include:

- 3-tier medium-duty racking

- 4-tier medium-duty racking

- 5-tier medium-duty racking

Using professional material storage racking helps investors save warehouse costs, management expenses, and labor. Medium-duty industrial racking features simple construction, flexible installation processes, and requires no special support tools.

Flow Rack for Material Storage

Flow racking for material storage consist of slightly inclined level surfaces with wheels and rollers. Stored goods slide downward by gravity through tilted slide bars installed on surfaces. Flow racks deliver high efficiency, enabling continuous rapid product dispatch.

Similar to push-back warehouse racking roller rack principles, pallets enter each rack level with forklift systems loading inventory at the front face and unloading at the rear. Storage capacity reaches 70-80% of warehouse floor area.

Applies First-In-First-Out (FIFO) rules. Depends on accompanying equipment including forklifts, pallets, and pallet sliding rail systems.

Pallet Material Racking

For material warehouses requiring rapid inbound/outbound operations, storing heavy loads with diverse product categories, Pallet Racking suits these conditions. This structure features wide aisles typically 3-4m, allowing forklifts to retrieve goods from any position.

Double Deep Material Racking

Double Deep racking with doubled Selective rack structure helps optimize by limiting forklift aisles, increasing storage capacity. However, flexibility decreases 50% compared to Selective racking.

Drive-In Material Racking

For businesses storing supplies, machinery of identical types with uniform dimensions and weights, requiring long-term storage without flexibility demands while maximizing floor area and warehouse height utilization, Drive-In racking is an excellent choice.

This solution minimizes forklift aisle areas, utilizing 90% of warehouse space. However, this system only accommodates one uniform pallet type meeting standardized quality and dimension requirements.

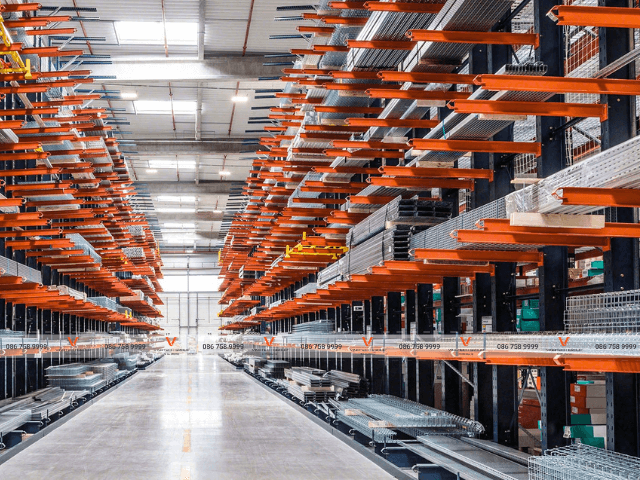

Cantilever Racking

For long, bulky materials, steel construction materials, wooden beams in furniture manufacturing warehouses, or plastic/steel pipes and sheet materials, cantilever racking provides the most optimal storage solution.

Cantilever racking specializes in storing long materials with manual or forklift retrieval. However, for storing shorter, smaller materials, additional sheet metal or mesh panels can be designed for diverse storage at reduced installation costs.

Material Storage Racking Price List

V-Slot Steel Racking Prices

Vinatech V-slot steel racking currently starts from 686,000 VND/unit. Detailed price list:

| Product Type | Dimensions (L×W×H) | Unit Price (VND/unit) |

|---|---|---|

| 2-tier steel rack | 1000×400×2000 mm | Contact |

| 3-tier steel rack | 1000×400×2000 mm | 686,000 |

| 3-tier steel rack | 1200×400×2000 mm | 799,000 |

| 4-tier steel rack | 1000×400×2000 mm | 947,000 |

| 4-tier steel rack | 1200×400×2000 mm | 1,096,000 |

| 5-tier steel rack | 1000×400×2000 mm | 1,184,000 |

| 5-tier steel rack | 1200×400×2000 mm | 1,371,000 |

| 5-tier steel rack | 1000×500×2000 mm | Contact |

| 5-tier steel rack | 1200×500×2000 mm | Contact |

| 6-tier steel rack | 1200×400×2000 mm | Contact |

Medium-Duty Material Racking Prices

Vinatech Group medium-duty material warehouse racking price list:

| Category | Unit Price (VND/unit) |

|---|---|

| 3-tier medium-duty C2000×R600×D2000 (bolted) | 2,955,000 |

| 3-tier medium-duty C2000×R600×D1500 (bolted) | 2,448,000 |

| 3-tier medium-duty C2000×R600×D1500 (welded) | 2,364,000 |

| 3-tier medium-duty C2000×R600×D2000 (welded) | 2,871,000 |

| 4-tier medium-duty C2000×R600×D2000 (bolted) | 3,672,000 |

| 4-tier medium-duty C2000×R600×D1500 (bolted) | 2,996,000 |

| 4-tier medium-duty C2000×R600×D2000 (welded) | 3,589,000 |

| 4-tier medium-duty C2000×R600×D1500 (welded) | 2,912,000 |

For detailed pricing on each product, please contact our hotline: 086.758.9999.

Custom Material Racking Design & Supply

For custom material storage racking with specific dimensions and load requirements, contact Vinatech Group immediately.

We currently supply top-quality material storage and material warehouse racking systems in the market. With over 14+ years of experience manufacturing and providing steel storage racking systems nationwide, Vinatech delivers products with the best quality and user safety.

Customer benefits at Vinatech:

- Access to highest quality products with superior load-bearing capacity and durability

- Factory-direct pricing without intermediary fees

- Free design drawings according to customer requirements

- Nationwide transportation and installation support

Vinatech currently accepts custom orders for material storage racking with specific dimensions and quantities, supplying non-standard racking per order specifications. Customers requiring material storage racking should contact Vinatech Group for consultation and fastest quotations.

Vinatech Group — Leading manufacturer and provider of warehouse racking and smart storage solutions in Vietnam

📞 Hotline: 086.758.9999

📧 Email: info@vinatechgroup.vn

🌐 Website: vinatechgroup.vn

Office locations:

- Hanoi: 15th Floor, TTC Building, 19 Duy Tan Street, Dich Vong, Cau Giay District

- Da Nang: 219-223 Pham Hung Street, Hoa Xuan, Cam Le District

- Ho Chi Minh City: Lot C2-7, N7 Road, Tan Phu Trung Industrial Park, Cu Chi District