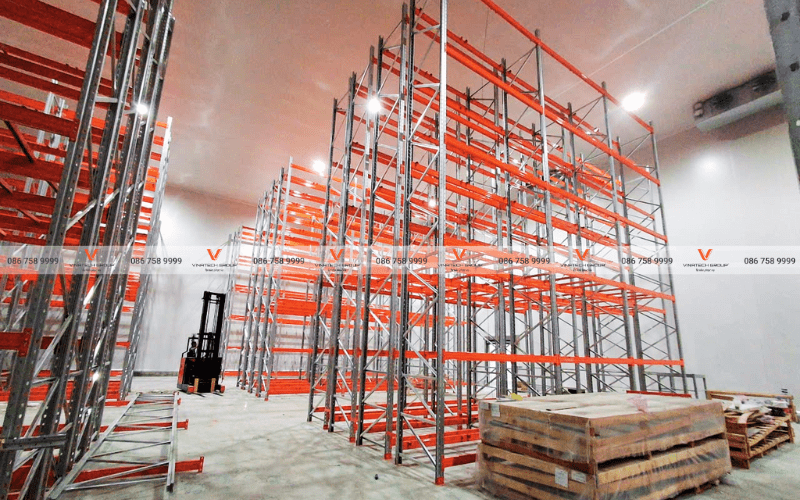

Food warehouse racking systems provide essential storage solutions for businesses handling perishable goods. To maximize storage efficiency, reduce costs, and simplify inventory management, many enterprises implement specialized food warehouse racking in their facilities.

What is Food Warehouse Racking?

Food warehouse racking refers to storage equipment designed for preserving produce, food products, seafood, and other goods requiring low-temperature environments. Unlike conventional warehouses, food storage facilities house specialty products demanding refrigeration or freezing, with unique arrangement and operational characteristics.

Many products cannot withstand ambient temperatures—seafood, fresh produce, dairy, and frozen foods require cold storage environments. Cold storage warehouse design is significantly more complex than standard facilities due to refrigeration and insulation requirements. Selecting appropriate racking is critical for scientific warehouse organization, cost optimization per square meter, and efficient inbound/outbound operations.

Beyond heavy load capacity, quality racking optimizes warehouse space more effectively than alternative storage methods. Multi-tier designs enable enterprises to maximize cold storage height, conserving valuable floor area. Robust column construction allows safe vertical expansion to ceiling height according to operational requirements without stability concerns.

Popular Food Warehouse Racking Systems

Selective Pallet Racking

The most widely adopted industrial steel racking configuration, Selective systems are particularly suited for industrial warehouses with heavy storage loads. Applications span numerous sectors including food storage, making Selective the premier consideration when purchasing food warehouse racking.

Selective racking’s outstanding advantage is flexible storage with easy compartment access. This benefit enables simple inbound/outbound operations, saving enterprise time. Inventory management and cycle counting are straightforward, ideal for warehouses with high receiving velocity.

Key Features:

- 100% pallet accessibility

- Flexible storage configurations

- Fast picking and retrieval

- Simple inventory management

- High-throughput compatibility

- FIFO/LIFO support

Drive-In Racking

Drive-In systems are renowned for simultaneously storing large volumes of high-load merchandise. These configurations minimize aisle space requirements while increasing storage area up to 70% of total warehouse footprint. Drive-In racking is especially suitable for homogeneous product storage.

Drive-In represents the most appropriate food warehouse racking among current configurations due to high-volume capacity. However, flexibility is reduced versus Selective systems; therefore, enterprises storing products with short preservation periods should avoid this configuration to ensure merchandise quality.

Key Features:

- Maximum storage density (70-85%)

- Minimal aisle requirements

- Ideal for uniform batch products

- LIFO or FIFO configurations available

- Cost-effective for high-volume operations

Double Deep Racking

Compared to Selective systems, Double Deep offers substantially greater storage capacity. For enterprises operating large-scale warehouses while maintaining reasonable retrieval times, Double Deep industrial racking provides optimal solutions. Systems comprise two back-to-back rack rows reducing aisle space while increasing storage volume.

However, Double Deep suits limited-variety merchandise with 50-60% selectivity access. Warehouse management requires careful, continuous supervision throughout all inbound/outbound processes.

Key Features:

- Double storage depth versus Selective

- Reduced aisle requirements

- 60-70% space utilization

- Requires specialized reach forklifts

- Best for moderate SKU diversity

Selection Criteria for Food Warehouse Racking

Prioritize Load Capacity

The primary consideration when selecting food warehouse racking is required storage load capacity. This critical factor applies universally across all warehouse types. Enterprises must calculate maximum pallet weight to select racking systems capable of supporting required merchandise volumes.

Insufficient rack capacity creates dangerous conditions—collapse, causing personnel injury, property damage, and enterprise reputation harm. Conversely, oversized capacity relative to storage needs wastes enterprise resources.

Consider Storage Density

Storage density is equally important as load capacity determination. Each racking type offers different density characteristics. Based on density calculations, enterprises determine aisle dimensions and maximum storage capacity, optimizing space utilization and warehouse area efficiency.

Calculate Inbound/Outbound Principles

Inbound/outbound protocols are critically important when selecting appropriate food warehouse racking. Depending on operational principles, enterprises must choose suitable racking to maximize storage area effectiveness and optimize utilization. Two prevalent warehouse protocols exist: FIFO (First In, First Out) and LIFO (Last In, First Out).

Typically, dry food products can apply LIFO methods to save retrieval time. Conversely, products with short expiration dates, fresh foods, and frozen items must utilize First In, First Out systems.

Match Forklift Equipment

If your warehouse already operates existing forklifts, select food warehouse racking compatible with those units. However, for new investments, prioritize merchandise storage characteristics, as each forklift type has different dimensions and reach capabilities. Choose forklifts compatible with storage racking to avoid situations where equipment cannot access merchandise on shelves.

Cold Storage Optimization

Food warehouses operating at refrigerated or frozen temperatures face additional considerations:

- Temperature Resistance: Racking materials and coatings must withstand temperature ranges from -25°C to +50°C without structural degradation or coating failure.

- Corrosion Protection: Cold, humid environments accelerate metal corrosion. Premium electrostatic coating (7 layers, 60-80 micron thickness) provides essential protection.

- Space Efficiency: Cold storage operation costs are substantially higher than ambient warehouses. Maximizing storage density through Drive-In or Double Deep configurations reduces refrigeration costs per pallet stored.

- Aisle Optimization: Minimizing aisle space reduces refrigerated volume, cutting energy consumption. However, balance with operational efficiency requirements.

- Maintenance Access: Cold environments make inspection and maintenance more challenging. Design should facilitate periodic safety checks without extended cold exposure for personnel.

Vinatech Group Food Storage Expertise

Vinatech Group supplies diverse food warehouse racking configurations across load capacities, delivering Vietnam’s highest quality at competitive pricing.

Material Excellence:

- 100% Q235 cold-rolled steel with CO-CQ certification

- 15-20% stronger than hot-rolled alternatives

- Superior rust resistance for cold/humid environments

- 15+ year operational lifespan

Advanced Coating Technology:

- 7-layer automated electrostatic application

- 60-80 micron thickness for cold storage durability

- Temperature-resistant formulation (-25°C to +50°C)

- 10+ year color retention without flaking

Food Industry Specialization:

- HACCP and food safety compliance design

- Load calculations for food product densities

- FIFO/LIFO optimization for expiration management

- Integration with cold storage refrigeration systems

Professional Services:

- Complimentary 2D/3D warehouse layout design

- Cold storage efficiency analysis

- Equipment compatibility assessment

- Installation with minimal operational disruption

- 5-10 year comprehensive warranty

- Periodic maintenance and inspection programs

Vinatech Group – Vietnam’s leading warehouse racking and smart storage solution provider

Hotline: +84 86 758 9999

Email: info@vinatechgroup.vn

Website: vinatechgroup.vn

Offices:

- Hanoi: 15F TTC Building, 19 Duy Tan St., Dich Vong, Cau Giay

- Da Nang: 219-223 Pham Hung St., Hoa Xuan, Cam Le

- Ho Chi Minh City: C2-7 N7 Road, Tan Phu Trung Industrial Park, Cu Chi