What are stacker crane? What advantages do these systems provide when integrated into warehouse operations? What requirements must facilities meet to implement stacker crane technology? join Vinatech Group to explore pricing information!

What is stacker crane?

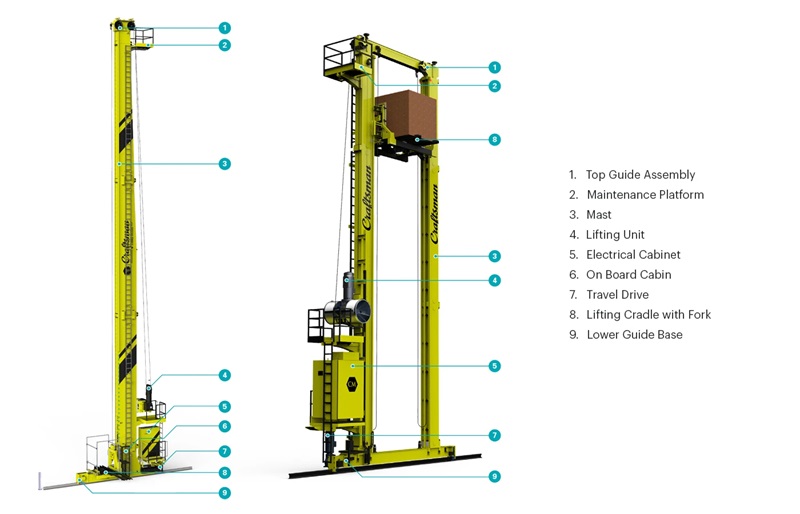

Stacker cranes are automated machinery designed to transport palletized goods within smart warehouse storage systems. These units move along length, height, and depth axes to stack and retrieve merchandise from racking structures with exceptional speed and precision. Stacker crane systems operate through warehouse management software controlling automatic goods distribution centers.

Stacker cranes represent indispensable components in AS/RS (Automated Storage and Retrieval Systems). Smart warehouse models equipped with this advanced technology significantly enhance warehouse productivity while maximizing space utilization to increase storage capacity. Furthermore, they reduce errors and risks associated with manual operations.

Technical Characteristics

Stacker cranes typically serve automated warehouse systems for pallet racking, suitable for diverse merchandise categories and various load capacities. Software-controlled systems deliver high precision performance.

AS/RS Stacker Crane Specifications:

- Load capacity: 3,000 kg maximum

- Height capability: Up to 45 meters

- Cold storage operation: Functions at temperatures down to -30°C

- Accessory compatibility: Multiple lifting attachments, platforms, and forks

- Heavy-duty welded mast: Continuous 360° rotation capability

- User-friendly design: Four-button mechanized motion control and operation panel

- Solid-state controls: Variable speed adjustment for precise, smooth positioning

- 4-rail insulated conductor system: Continuous, trouble-free power delivery

- Mast-mounted headlights: Floor illumination during operations

- Enclosed wheel carriages: Derailment prevention within bridge beams

Operational Advantages

Stacker crane integration delivers substantial warehouse benefits:

- Enhanced Productivity: Enables 24/7 warehouse operations. Storage and retrieval execute in combined movements (dual-cycle operations), providing high system flexibility.

- Complete Automation: Automatic operation streamlines warehouse management while eliminating manual task errors.

- Maximum Space Utilization: Stacker cranes reach heights up to 45 meters in narrow aisles measuring only 1.5 meters wide.

- Double and Multiple Depth Capability: Systems operate seamlessly with diverse racking types including flow racks, pallet racking systems, Selective racking, and Double Deep configurations.

- High Flexibility: Customizable design meets specific requirements for load capacity, height, and inventory rotation preferences.

- Safety Enhancement: Stacker cranes handle pallet storage positions with extreme precision. Additionally, they significantly reduce handling equipment traffic, enhancing warehouse safety.

- Comprehensive Warehouse Solution: Integrated with WCS (Warehouse Control Systems) and WMS (Warehouse Management Systems), stacker cranes form essential ASRS components. This configuration represents the future solution for cost and resource savings in merchandise storage.

Implementation Requirements

AS/RS stacker crane deployment necessitates meeting specific criteria:

- Compatible warehouse racking systems

- Merchandise weight limitations during transport operations

- Narrower aisle space requirements versus conventional forklifts

- Warehouse system stability and structural integrity

- Compliance with OSHA, NEC, and CMAA standards and regulations

Operating Principles

Stacker cranes provide complete automation for warehouse pallet storage and retrieval operations.

These machines execute three movement types: longitudinal (traveling along aisles), vertical (operating at height), and horizontal (fork extension into racking depth for pallet placement or removal).

Typical AS/RS Warehouse Operations:

- Pallet Transport to Aisle: Adjacent conveyor delivers pallet to aisle endpoint

- Pallet Reception: System lifts pallet and positions on lifting platform

- Aisle Movement: To transport pallets to WMS-designated positions, stacker cranes travel along aisles with simultaneous translational (horizontal) and lifting movements

- Pallet Storage: System extends forks, inserting pallet into racking at designated position

- Alternative Pallet Retrieval: After storing pallet, stacker crane moves to different position for pallet extraction (dual-cycle operation)

- Pallet Discharge: Crane returns to aisle endpoint, placing pallet on conveyor for warehouse exit

Industry Applications

Stacker crane-integrated storage systems adapt to diverse warehouse requirements across industrial and commercial material handling operations.

Typical Applications:

- Warehousing and Distribution Centers: Automated distribution centers frequently employ stacker cranes for moving goods, materials, and equipment within and between locations. Compared to forklifts and conveyor systems, they offer superior flexibility with reduced aisle width constraints.

- Metal Processing Facilities: Metal handling operations involve storing, transporting, and pouring molten materials, creating significant health and safety risks for personnel without appropriate equipment. Stacker cranes and related systems provide stable, durable, reliable solutions for safe material handling.

- Automotive Manufacturing Facilities: Production operations utilize stacker cranes for lifting, transporting, and positioning automotive components across various activities including assembly and storage.

- Transportation and Logistics Facilities: AS/RS systems see widespread deployment in shipping and logistics facilities, particularly large-scale operations receiving/dispatching substantial merchandise volumes. Stacker cranes typically comprise critical components of these systems.

- Cold Storage: These machines operate at temperatures as low as -30°C.

Stacker cranes represent flexible storage solutions meeting diverse company requirements. They have proven effectiveness across multiple industrial sectors including food processing, metallurgy, automotive, pharmaceuticals, and others.

Vinatech Group: AS/RS Implementation Specialist

Stacker cranes are indispensable equipment for transporting palletized goods in AS/RS or smart warehouse systems. Vinatech Group proudly delivers comprehensive smart warehouse solutions helping enterprises optimize warehouse management processes, enhance operational efficiency, and increase profitability.

With experienced engineering teams possessing deep expertise in automation technology and IoT, we commit to providing customers optimal solutions matching specific enterprise requirements and budgets.

Vinatech Group Smart Warehouse Solutions:

Warehouse Management Systems (WMS)

Automates warehouse management processes from A to Z including receiving, shipping, inventory counting, goods allocation, optimizing operational efficiency and minimizing errors. Provides detailed real-time merchandise status information, enabling easy warehouse tracking and management.

Automated Guided Vehicles (AGV)

Automatically moves warehouse goods, reducing manual labor, enhancing productivity and worker safety. Multiple robot types suit diverse enterprise requirements including towing AGVs, lifting AGVs. Advanced navigation system integration using laser, camera, RFID enables safe, efficient movement.

Automated Storage & Retrieval Systems (AS/RS)

Automatically stores and retrieves goods in high-bay warehouses, optimizing warehouse area and reducing operational costs. Integrates with WMS for efficient crane control and management.

Automated Conveyor Systems

Automates goods transportation, enhancing operational efficiency, optimizing costs, and increasing enterprise profitability. Systems include various motor-controlled conveyors moving goods between locations automatically without human intervention.

Service Commitments

With advanced warehouse solutions and professional services, we commit to helping enterprises enhance operational efficiency, optimize costs, and increase profitability.

Our Advantages:

- Experienced engineering team with automation expertise

- Customized solutions matching specific requirements

- Comprehensive project management from design to installation

- Integration with existing warehouse systems

- Training and technical support programs

- Long-term maintenance and optimization services

- ROI analysis and performance monitoring

Vinatech Group – Vietnam’s leading warehouse racking and smart storage solution provider

Hotline: +84 86 758 9999

Email: info@vinatechgroup.vn

Website: vinatechgroup.vn

Offices:

- Hanoi: 15F TTC Building, 19 Duy Tan St., Dich Vong, Cau Giay

- Da Nang: 219-223 Pham Hung St., Hoa Xuan, Cam Le

- Ho Chi Minh City: C2-7 N7 Road, Tan Phu Trung Industrial Park, Cu Chi