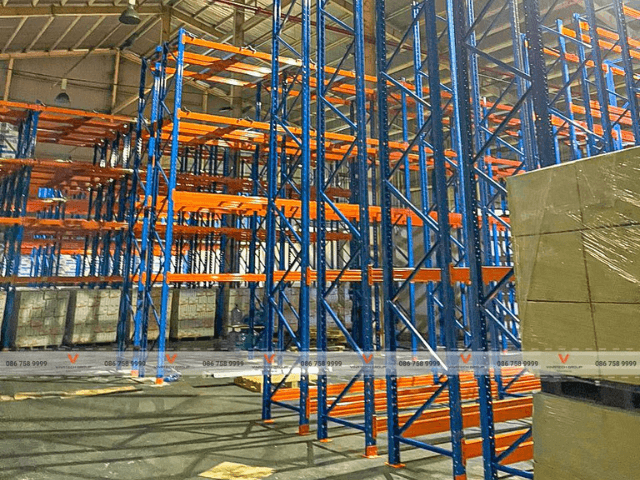

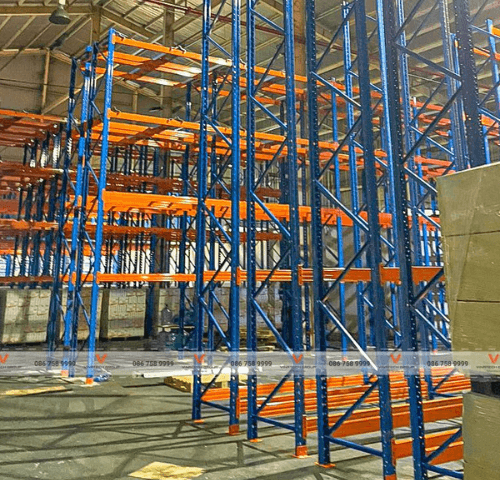

Double Deep Racking is a high-density pallet racking system that has become a popular choice for modern warehouses. By positioning two selective racking rows back-to-back, this innovative design effectively doubles storage capacity while minimizing the number of required aisles. It is the ideal solution for logistics centers, manufacturing plants, food and beverage storage, and cold storage facilities that demand both high-density storage and efficient product accessibility. Discover the complete solution with Vinatech Group.

What is Double Deep Racking?

Double Deep Racking is a heavy-duty storage system created by installing two rows of standard Selective Racking back-to-back. This configuration eliminates redundant aisles, significantly increasing the storage density of your facility.

This system serves as an excellent middle-ground between Selective Racking (which offers high accessibility but lower density) and Drive-In Racking (which provides maximum density but limited accessibility). Double Deep optimizes your floor space while maintaining a respectable level of product selectivity.

Operations are based on the LIFO (Last-In, First-Out) principle, where the last pallet stored is the first one to be retrieved. To access the rear pallet position, a specialized forklift with a telescopic or pantograph reach mechanism is required.

Technical Specifications

Double Deep racking is a smart investment for businesses looking to expand storage capacity without increasing their physical footprint.

| Specification | Details |

| Max Storage Height | Up to 16 meters |

| Upright Frame | Perforated Omega Profile |

| System Depth | 1,200mm – 4,500mm |

| Storage Density | Optimizes warehouse space by up to 50% |

| Capacity | 2 – 4 pallets per bay |

| Max Load Capacity | Up to 2,000 kg per level |

| Material | High-quality, powder-coated steel |

| Warranty | 10 years for the entire project |

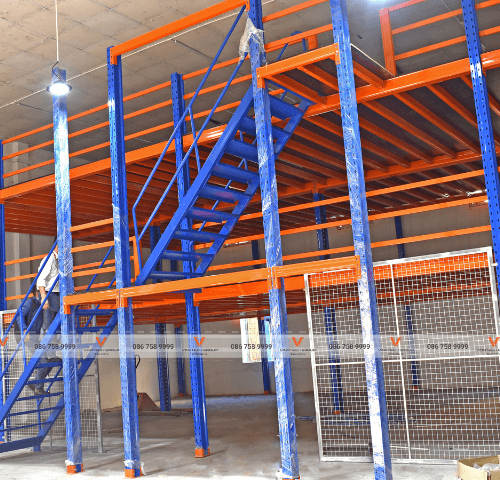

Core Components of the Double Deep System

The stability and safety of the Double Deep system are ensured by its robust, engineered components:

- Upright Frames: The primary vertical supports that bear the entire system’s load.

- Load Beams: Horizontal beams that connect the uprights and support the pallets. Their height is fully adjustable.

- Bracing: Includes horizontal and diagonal struts that connect the uprights, forming a rigid frame and preventing sway.

- Safety Accessories:

- Post Protectors: Shield upright columns from potential forklift collisions.

- Safety Barriers: Protect the ends of racking aisles.

- Pallet Stop Beams: Prevent pallets from being pushed too far back

Advantages and Disadvantages of Double Deep Racking

Key Advantages:

☑️ Increased Storage Density: Boosts storage capacity by up to 50% compared to standard Selective racking by reducing aisles.

☑️ Enhanced Warehouse Capacity: Effectively doubles the number of pallets stored in the same floor area.

☑️ Heavy-Duty Performance: A robust structure designed to handle heavy industrial goods, with capacities from 1,000 kg to 4,000 kg per level.

☑️ Exceptional Durability: The powder-coated steel frame resists rust and corrosion, ensuring a lifespan of over 10 years, even in demanding cold storage environments.

☑️ System Flexibility: A bolt-together construction allows for easy installation, relocation, and adjustment of beam levels.

Considerations:

❌ Requires Specialized Forklifts: Mandates the use of deep-reach or telescopic fork trucks, which can increase initial investment costs.

❌ Limited Pallet Accessibility: Offers direct access to only 50% of stored pallets, reducing selectivity compared to Selective systems where access is 100%.

❌ LIFO Inventory Management: Not suitable for products with short shelf lives or those requiring strict FIFO (First-In, First-Out) stock rotation.

❌ Slower Pick/Put-Away Times: Retrieving the rear pallet is a two-step process that requires more time and careful maneuvering than single-deep systems.

Operational Mechanism: The LIFO Principle in Action

The Double Deep system operates exclusively on the LIFO (Last-In, First-Out) principle, managed by a reach truck.

- Loading Process (Put-Away):

- Step 1: The forklift operator extends the reach mechanism to place the first pallet into the rear storage position (the second slot from the aisle).

- Step 2: After securing the first pallet, the operator retracts the forks and places the second pallet in the front position, blocking the first pallet.

- Unloading Process (Picking):

- Step 1: To access the rear pallet, the operator must first remove the front pallet.

- Step 2: Once the front position is clear, the operator extends the reach mechanism to retrieve the rear pallet.

This mechanism makes the system highly efficient for storing multiple pallets of the same SKU.

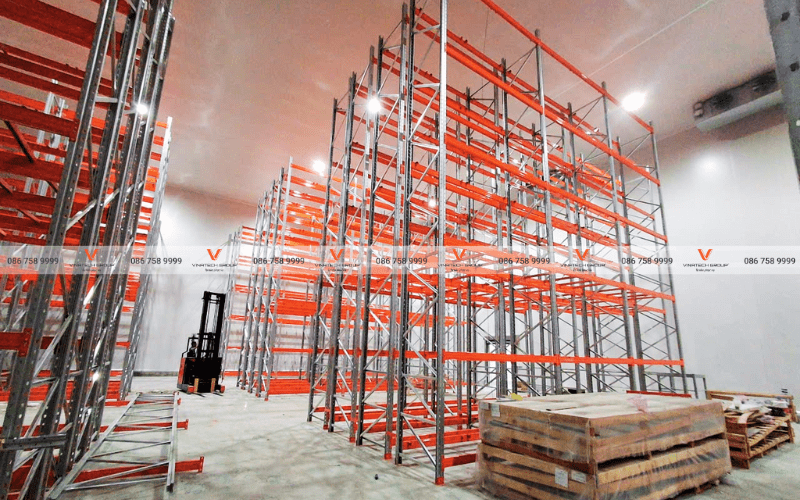

Ideal Applications for Double Deep Racking

This system is most effective in warehouses that store large volumes of homogenous products with a medium turnover rate. Key industries include:

- Beverages: Beer, soft drinks, bottled water (uniform, heavy pallets).

- Packaged & Frozen Foods: Instant noodles, canned goods, powdered milk.

- Pharmaceuticals & Cosmetics: Boxed medicines, chemicals, and cosmetic products.

- Electronics & Automotive Parts: Televisions, printers, home appliances, and crated auto parts.

- Fast-Moving Consumer Goods (FMCG): Detergents, paper products, and household goods in cartons.

Double Deep vs. Selective Racking: A Comparison

| Criteria | Double Deep Racking | Selective Racking |

| Storage Density | High | Low |

| Pallet Accessibility | 50% | 100% (Direct access to every pallet) |

| Operating Principle | LIFO | FIFO |

| Forklift Type | Reach Truck Required | Most standard types |

| Handling Speed | Medium | Fast |

| Initial Cost | Medium | Low |

| Best Suited For | Homogenous, high-volume SKUs | Diverse, low-volume SKUs |

Why Choose Vinatech Group for Your Double Deep Racking Project?

With 14 years of industry leadership, Vinatech Group specializes in designing and implementing optimized warehouse storage solutions.

- Advanced Manufacturing: We operate two state-of-the-art factories in Northern and Southern Vietnam, covering 50,000 m², to handle large-scale production.

- Nationwide Network: Our robust network includes over 200 distributors and a dedicated team of 500 experienced professionals.

- Proven Track Record: We have successfully completed over 50,000 projects across a wide range of industries.

- Certified Quality: Our production lines are ISO 9001:2015 certified and utilize cutting-edge technology.