VNA Racking (Very Narrow Aisle Pallet Racking) is a heavy-duty pallet racking system designed with extremely narrow aisles (typically 1.7 m – 2.0 m), allowing for maximum storage capacity in a limited warehouse footprint. By minimizing aisle width while maximizing height and depth, VNA racking can save up to 40% of floor space compared to conventional systems. What are the advantages and disadvantages of using VNA racking? Vinatech Group will help you understand everything about VNA racking to make the most suitable choice for your storage needs.

What is VNA Racking (Very Narrow Aisle)?

VNA (Very Narrow Aisle) racking is a warehouse storage system engineered for ultra-narrow aisles (usually 1.7 m – 2.0 m). It maximizes storage area by reducing the space between rack rows while still providing 100% direct access to every pallet thanks to specialized narrow-aisle forklifts.

Key Features

- Increases storage capacity by 40–50% compared to standard Selective racking due to narrow aisles.

- 100% direct pallet access enables fast loading/unloading, ideal for warehouses with high turnover and diverse SKUs.

- High load capacity from 500 kg – 2500 kg per pallet, durable, and easily expandable – suitable for industrial goods or distribution centers.

- Storage height up to 12–17 m (depending on forklift type), fully utilizing vertical space.

- Requires a highly flat warehouse floor and specialized narrow-aisle trucks (guided by rails or wire/laser) for safe and efficient operation.

VNA (Very Narrow Aisle) racking features ultra-narrow aisles for maximum space utilization

Applications

- Heavy industrial warehouses and logistics centers.

- Warehouses requiring high-frequency inbound/outbound operations and detailed inventory control.

- Space-constrained facilities needing maximum storage density with fast, direct pallet access.

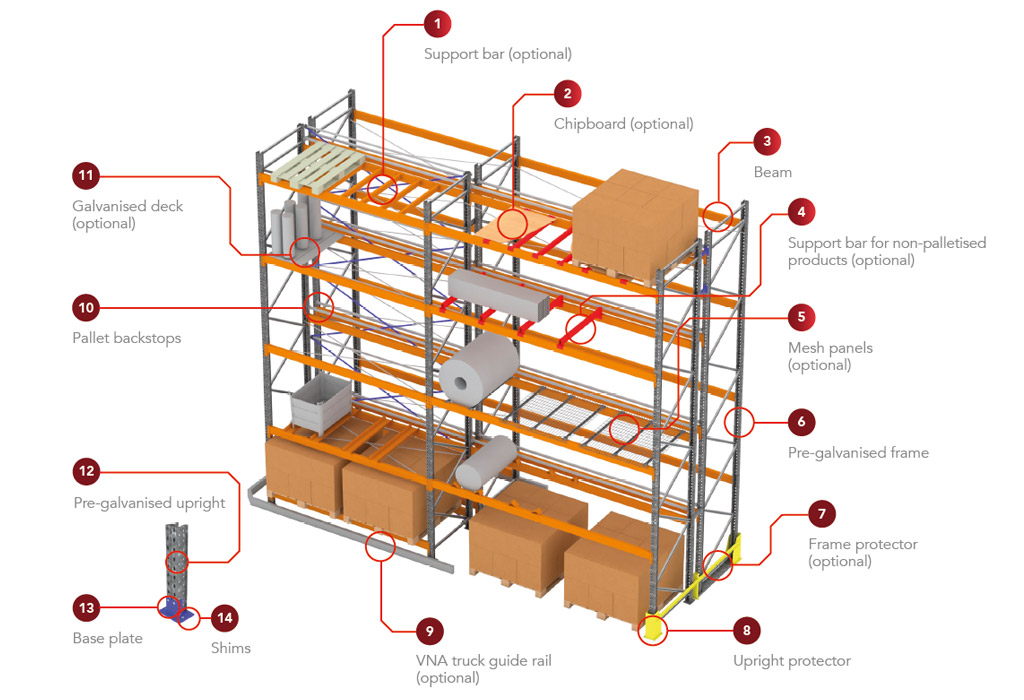

Structure of VNA Racking

The structure of VNA (Very Narrow Aisle) racking includes: Omega upright frames, horizontal and diagonal bracing, beams, additional tie members (if required), and most importantly, guide rails that ensure precise forklift movement in narrow aisles. This design maximizes warehouse space and storage density.

Main components of VNA racking:

- Omega upright frames: Primary load-bearing elements, made from high-strength steel with electrostatic powder coating for durability and safety.

- Horizontal and diagonal bracing: Connects upright frames, evenly distributes forces, enhances stability, and minimizes sway during operation.

- Beams: Connect between uprights, providing the direct support surface for pallets.

- Tie members: Link rows or frames for added rigidity and system uniformity.

- Guide rails: Fixed to the floor, guiding the forklift precisely through narrow aisles and reducing collision risk with rack legs.

- Safety barriers: Installed close to upright bases to protect the racking and operators from forklift impacts.

VNA racking increases warehouse storage capacity by 40%

Key Characteristics of Narrow Aisle (VNA) Racking

Narrow Aisle (VNA) racking is designed with aisles as narrow as 1.5 m – 2.0 m, maximizing warehouse floor utilization and increasing storage capacity by 40–50% compared to Selective racking.

Outstanding Features of VNA Racking

- Space optimization: VNA narrows aisles to approximately 1.6 m – 2.2 m (vs. 3 m – 4 m for Selective), resulting in 40–50% more storage capacity in the same footprint.

- Maximum height utilization: Designed for heights from 12 m to 17 m, making excellent use of vertical space – especially suitable for high-ceiling warehouses.

- 100% pallet selectivity: Despite high density, every pallet position remains directly accessible without moving other loads – supporting flexible FIFO or LIFO inventory management.

- Improved operational efficiency and safety: Uses specialized narrow-aisle forklifts (turret trucks, guided reach trucks) with rail, wire, or laser guidance for precise movement in tight aisles.

- High load capacity: Manufactured from premium steel, supporting 500 kg to 2500 kg per pallet – ideal for heavy industrial storage.

Applications of Narrow Aisle (VNA) Racking

VNA pallet racking – designed for ultra-narrow aisles – is an advanced industrial solution typically implemented in warehouses that need to maximize floor space while maintaining fast, direct access to every pallet.

Thanks to its optimized height utilization and minimized aisle width, VNA delivers superior performance for the following warehouse types:

Warehouses requiring fast, uninterrupted goods flow: Direct access to each pallet without relocating others makes VNA ideal for high-frequency distribution centers handling frequent and accurate order processing.

Warehouses with diverse SKUs or multiple product types: Perfect for non-uniform goods (varying sizes and categories) that require flexible, item-specific organization.

High-turnover environments: When goods need continuous inbound and outbound movement, VNA shortens picking time while maintaining order and supporting customized FIFO/LIFO strategies.

Facilities with limited floor space but adequate ceiling height: Maximizes storage density vertically without requiring horizontal expansion.

The above is detailed information about VNA racking provided by Vinatech Group. We hope this helps you better understand the popular Narrow Aisle storage solution. If you have any further questions or needs, please contact us via hotline for expert consultation!

Frequently Asked Questions

1. What is the maximum load capacity per pallet for VNA racking?

Vinatech VNA racking supports 500 – 2500 kg per pallet (standard typically 800–1500 kg), with heavy-duty custom designs available and high safety factors per ISO standards.

2. What is the minimum aisle width for VNA racking?

Vinatech VNA racking requires aisles of only 1.5–2.0 m (commonly 1.6–1.8 m with VNA trucks), significantly saving space compared to Selective racking (3.5–4 m aisles).

3. Does VNA racking operate on FIFO or LIFO?

VNA racking supports both FIFO and LIFO flexibly (depending on layout), but primarily enables 100% direct pallet access, making it suitable for diverse inventory management.

4. Which forklift is best suited for VNA racking?

Specialized VNA trucks (turret trucks, guided reach trucks with rail or laser navigation) capable of 180–360° fork rotation, high lift heights, and precise movement in narrow aisles.

5. Can VNA racking be easily expanded or relocated?

Yes, Vinatech VNA racking features a bolted modular design, allowing easy addition of rows or relocation when expanding the warehouse, though guide rails may require realignment.

Contact Vinatech Group today for a free consultation, on-site survey, detailed 3D design, and the most competitive pricing in 2026!

Hotline: 086.758.9999 | Email: info@vinatechgroup.vn

Website: vinatechgroup.vn

We commit to custom manufacturing, export-quality standards, and professional nationwide installation.