Pallet Flow Racking (also known as Roller Conveyor Racking or Carton Flow Rack for lighter loads) is a modern warehouse racking system that uses inclined rollers to allow goods to automatically slide from the loading end to the picking end by gravity. This intelligent storage solution operates strictly on the FIFO (First In, First Out) principle – first goods in are first goods out – optimizing inventory management, reducing stock stagnation, and accelerating goods turnover.

At Vinatech Group – Vietnam’s leading manufacturer and provider of intelligent warehouse racking solutions – we deliver high-quality Flow Racking systems manufactured to international standards, suitable for warehouses of all scales, from light to heavy-duty applications.

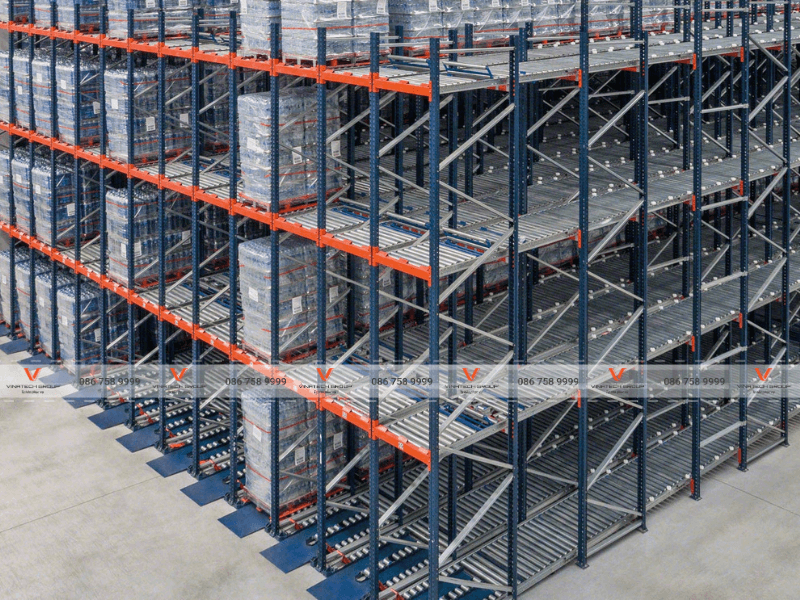

Structure of Pallet Flow Racking

Vinatech Flow Racking supports loads of 1000 kg per pallet (up to 3000 kg with custom heavy-duty design). Maximum height reaches up to 10 m, depending on warehouse structure and requirements. The system is fabricated from premium high-strength steel frames, ensuring optimal durability and safety. Key components include:

- Upright frames and load-bearing beams as the primary structure.

- Roller rails equipped with high-quality plastic or steel rollers (diameter selected based on load).

- Support components: Speed-control brake rollers, pallet stoppers, pallet guides, diagonal braces for enhanced stability.

- Safety features: Fixed base plates, secure bolted connections, easy assembly and height adjustment.

The standard incline (typically 3–5 degrees) ensures smooth, energy-free movement of goods.

Flow Racking system operates on a fully gravity-based automatic mechanism

Common Types of Flow Racking

Based on load capacity and product type, we classify into two main categories:

- Carton Flow Rack (for light goods): Designed for cartons, plastic trays, small parts (load capacity 50–500 kg per level). Ideal for electronics components, spare parts, factory supplies, and assembly lines. Manual picking by operators or hand carts.

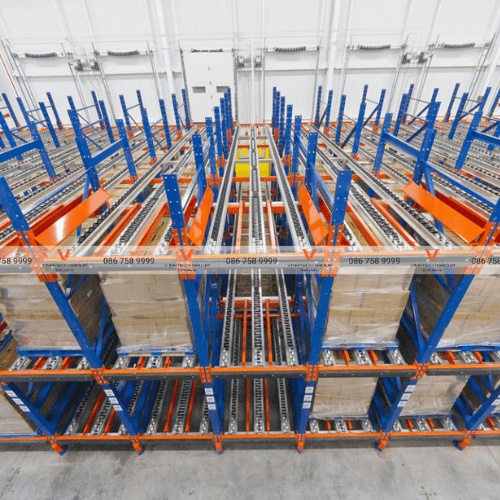

- Pallet Flow Rack (for heavy goods): Designed for standard pallets (load capacity 1000–2000 kg per pallet or higher with custom design). Forklifts load pallets at the higher (infeed) end and retrieve at the lower (discharge) end. Perfect for logistics, food, and fast-moving consumer goods (FMCG) warehouses.

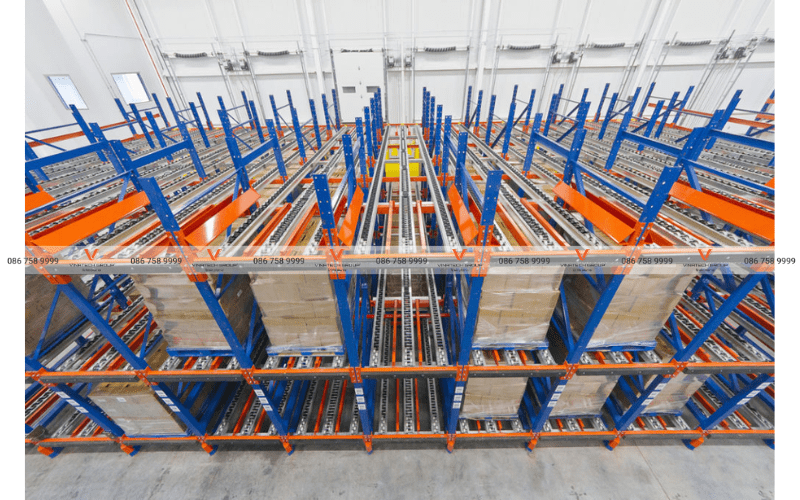

Operating Principle of Flow Racking

The system runs entirely on gravity and strictly adheres to FIFO (First In, First Out) – first goods loaded are first goods retrieved:

- Loading: Goods (pallets or cartons) are placed at the higher (infeed) end of the rack. Gravity causes them to slide along the rollers toward the lower (discharge) end.

- Unloading: When a pallet or carton at the discharge end is removed, the next item automatically slides forward to fill the gap immediately.

This process ensures continuous goods flow without forklifts entering deep into lanes, saving significant time and labor. The entire operation requires no electricity, delivering high efficiency and low maintenance costs.

Key Advantages of Flow Racking

- Space optimization: Significantly reduces aisles between lanes (increases storage density by 70–80% compared to conventional racking).

- Energy and cost savings: Goods move by gravity – no power, motors, or pushing devices required.

- Scientific inventory management: Strict FIFO prevents old stock buildup – ideal for food, pharmaceuticals, short-shelf-life items, or high-turnover goods.

- Faster throughput: Reduces picking time, saves labor, and improves overall logistics efficiency.

- Safety and durability: Robust bolted construction, easy height adjustment, long service life.

Applications

- Flow Racking is suitable for the following warehouse types:

- Logistics and e-commerce distribution centers.

- Manufacturing plants for components and spare parts.

- FMCG, food, and pharmaceutical warehouses.

- Assembly lines and distribution operations.

Are you looking for a solution for light-load carton storage or heavy-duty pallet flow racking? Contact Vinatech Group right away for a free site survey, detailed 3D design, and the most competitive pricing!

Hotline: 086.758.9999 | Email: info@vinatechgroup.vn

Website: vinatechgroup.vn

Vinatech Group commits to custom manufacturing, export-quality standards, fast nationwide installation, and professional service.

Frequently Asked Questions

1. What is the maximum load capacity per pallet for Flow Racking?

Vinatech Flow Racking supports 1000 kg per pallet (up to 3000 kg with custom heavy-duty design).

2. What materials are used for the frames and rollers in Flow Racking?

- Frames: Cold-rolled steel or box-section steel with electrostatic powder coating (resistant to warping and high strength).

- Rollers: Galvanized steel, stainless steel, or aluminum alloy (rust-resistant, low friction, high load capacity).

3. Can Flow Racking be customized in width and length?

Yes, Vinatech offers full customization of width, length, number of levels, depth, and configuration to match pallet sizes and warehouse space.

4. What factors affect the installation cost of Flow Racking?

Cost depends on system size, load capacity, number of levels, roller material, transportation, and special technical requirements. Vinatech provides optimal

pricing through direct in-house manufacturing, with factories in both Northern and Southern Vietnam to minimize logistics costs.

5. What is the warranty period for Flow Racking?

Vinatech Group provides a standard 12-month warranty (extendable up to 3 years depending on the project), with nationwide on-site maintenance support.

Contact Vinatech Group today for a free consultation, on-site survey, detailed 3D design, and the best 2026 pricing!

Hotline: 086.758.9999 | Email: info@vinatechgroup.vn

Website: vinatechgroup.vn

Reviews

There are no reviews yet.