Fabric roll storage racking demand continues growing as textile manufacturing facilities expand across Vietnam. The textile industry remains a key industrial sector experiencing robust development in recent years. Selecting optimal, cost-effective fabric roll warehouse racking requires understanding capacity requirements, warehouse space, and load specifications. join Vinatech Group to explore pricing information!

4+ Common Fabric Roll Racking Types

Fabric racking requirements for sewing workshops, companies, or enterprises vary depending on purpose, warehouse space, fabric quantity, and load capacity. Fundamentally, fabric racking must be sturdy steel construction with multiple tiers using MDF boards, stainless steel decks, or sheet metal platforms.

Multi-Purpose V-Slot Fabric Racking

V-slot steel racking This versatile steel fabric display racking handles fabric roll weights approximately 70-100 kg/level. Due to light load capacity, this racking only suits small sewing facilities storing moderate fabric quantities, or fabric retail shops and market stalls displaying merchandise for sale.

For fabric stores and small sewing shops seeking affordable warehouse racking, this type offers reasonable costs compared to fabric and textile storage racking requiring larger load capacities.

Medium-Duty Fabric Roll Racking

This racking type is widely used in medium-sized companies and enterprises. Load capacity ranges from 200kg to 500 kg/level with standard colors including orange, blue, and gray.

Medium-duty fabric roll racking perfectly suits storing fabrics and garments in warehouses, offering high load capacity and versatile usage for semi-finished goods, accessories, and finished products awaiting dispatch.

This racking type is manufactured from solid steel materials connected by bolts, making relocation and level spacing adjustments easy according to usage requirements. medium-duty racking frames typically use perforated Omega posts. Rack surfaces include sheet metal decks, wire mesh panels, or plywood, MDF, and Okal boards.

Selective Fabric Racking

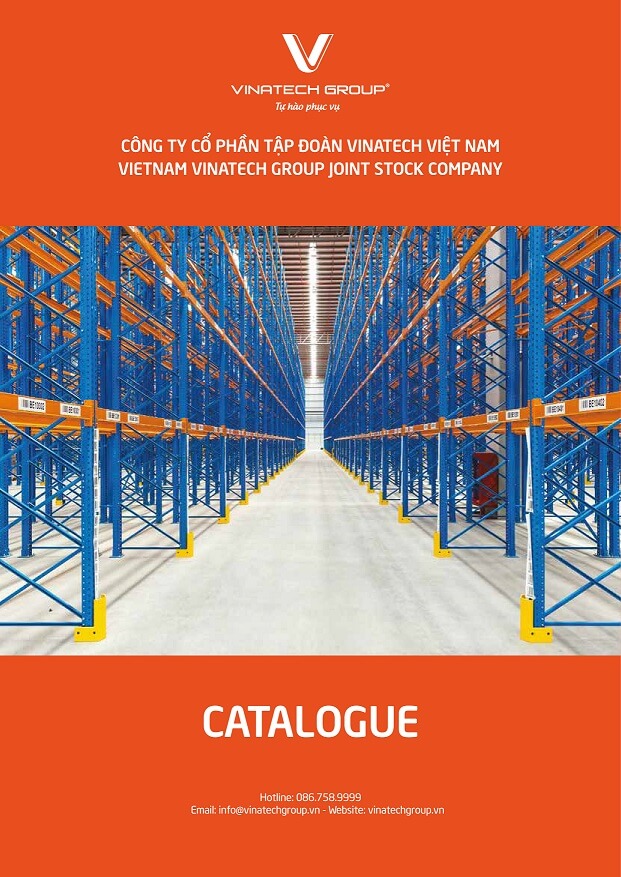

Selective warehouse racking is chosen for heavy-duty warehouses, commonly used in large companies and enterprises storing substantial fabric roll volumes.

Key advantages include accommodating diverse fabric types. Selective Pallet Racking becomes an excellent choice for all manufacturing facilities producing various fabrics, garments, or fashion items.

Drive-In Fabric Roll Racking

Drive-In racking is a heavy-duty steel fabric storage model suitable for warehouses requiring extremely high storage density. This system can maximize workshop floor area up to 70% by minimizing aisle space.

However, this racking type offers poor fabric accessibility, only suiting certain businesses or those producing single fabric types.

Fabric Roll Racking Selection Tips

Select Appropriate Load Capacity Racking

Choosing suitable racking not only optimizes warehouse space but protects fabric quality, minimizing damage risks and losses—especially critical for textile companies storing large fabric and garment volumes.

Popular heavy-duty fabric roll racking types:

- Selective racking: Common type allowing fabric roll retrieval from multiple directions, suitable for warehouses with high inbound/outbound frequency

- Drive-in racking: Optimizes storage space, appropriate for warehouses storing large fabric roll quantities with infrequent dispatch

- Cantilever racking: Specifically designed for long, heavy fabric rolls, making retrieval more convenient

Additionally, investors should select racking made from electrostatically painted steel with rust resistance, ensuring high durability and safety for long-term fabric roll storage.

Warehouse racking should feature round shaft bars or support brackets helping secure fabric rolls and prevent moisture damage.

Meet Load Capacity, Dimension, and Material Requirements

Fabric warehouse management has never been simple work, requiring inventory control, quantity and quality monitoring, and close merchandise classification. Moreover, frequent warehouse inbound/outbound operations demand clear warehouse organization facilitating rapid merchandise location.

When selecting fabric roll racking, consider these important criteria:

- Rack load capacity: Investors must clearly determine fabric roll weights to select appropriate load capacity racking, avoiding overload damage situations

- Durable materials: Prioritize electrostatically painted steel ensuring durability and corrosion resistance in warehouse conditions

- Rack dimensions: Compatible with warehouse area and fabric roll length, typically ranging from 1m-3m

Vinatech Group 2025 Fabric Roll Racking Price List

As a leading brand in Vietnam’s racking manufacturing sector, Vinatech Group has established credibility with over 14 years of experience, providing high-quality warehouse racking solutions for numerous large enterprises.

Vinatech owns two large-scale factories located in Hanoi and Ho Chi Minh City, equipped with automated machinery systems imported from Europe, ensuring internationally standardized production processes.

Vinatech Group factories apply strict quality control processes following Japanese standards, delivering highly durable racking products with excellent load-bearing capacity meeting diverse storage needs.

Commonly used fabric roll racking price list:

| Racking Type | Reference Price (VND) |

|---|---|

| Selective racking for fabric warehouse | 2,000,000 – 5,000,000/unit |

| Mezzanine flooring | 500,000 – 2,000,000/m² |

| Medium-duty racking | 1,000,000 – 3,000,000/unit |

| V-slot racking | 1,000,000/unit |

| Stackable steel pallets | From 1,500,000/piece |

Note: Depending on usage requirements, each customer will have different designs. Therefore, contact us immediately for specific and accurate consultation.

Vinatech Group has successfully deployed warehouse racking installation projects for numerous large corporations and enterprises including Vietjet, Vietcombank, Hanacans, Vietnam Oil and Gas Construction Corporation, Premo Vietnam, and more.

Vinatech Group — #1 manufacturer and provider of warehouse racking and smart storage solutions in Vietnam

📞 Hotline: 086.758.9999

📧 Email: info@vinatechgroup.vn

🌐 Website: vinatechgroup.vn

Office locations:

- Hanoi: 15th Floor, TTC Building, 19 Duy Tan Street, Dich Vong, Cau Giay District

- Da Nang: 219-223 Pham Hung Street, Hoa Xuan, Cam Le District

- Ho Chi Minh City: Lot C2-7, N7 Road, Tan Phu Trung Industrial Park, Cu Chi District