Heavy Duty Racking

1. What is a Heavy-Duty Racking System?

Heavy-duty pallet racking systems are designed to store large, high-weight goods such as steel coils, construction materials, or industrial equipment. With over 14 years of experience, Vinatech Group provides high-quality, customizable heavy-duty racks to optimize warehouse space and improve operational efficiency.

2. Top 10+ Heavy-Duty Racking Types in 2025

2.1. Selective Pallet Racking

The most popular racking system for industrial warehouses.

- Load capacity: 500 – 5000 kg/pallet

- 100% direct pallet access from both sides

- Easy to adjust beam levels and compatible with most forklifts

- Cost-effective and flexible for multi-SKU warehouses

2.2. Double Deep Racking

Two Selective racks installed back-to-back to double storage capacity.

- Space-saving up to 50%

- Load capacity: 2000 – 4000 kg/level

- Operates on the LIFO principle

- Requires a specialized reach truck

2.3. Drive-In Racking

Ideal for cold storage and bulk storage warehouses.

- Space utilization up to 80%

- Load capacity: up to 3000 kg/level

- Suitable for low-SKU, high-volume goods

- Reduces aisles and maximizes cubic storage space

2.4. Pallet Flow Rack

Also called gravity flow racking.

- Uses roller tracks for automatic pallet movement

- Operates under FIFO principle

- Load capacity: 1000 – 2000 kg/pallet

- Ideal for food, pharmaceutical, and distribution centers

2.5. Push Back Racking

Each pallet pushes the previous one backward.

- Load capacity: 1000 – 2000 kg/level

- Stores 2–4 pallets per lane

- Improves space usage by up to 70%

- Operates under LIFO method

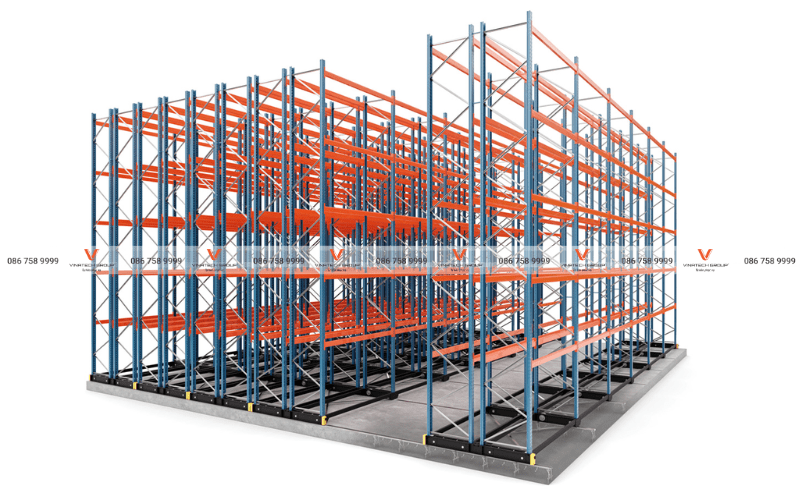

2.6. Mobile Racking

High-density storage solution where racks move on floor rails.

- Load capacity: 2000 – 3500 kg/level

- Motorized movement via remote or automatic control

- Reduces the number of fixed aisles

- Perfect for cold or compact warehouses

2.7. Shuttle Racking

Shuttle Racking Automated solution using shuttles running on rails.

- Load capacity: 500 – 1500 kg/pallet

- Controlled via remote or WMS system

- Works efficiently in cold storage or high-throughput warehouses

2.8. Mezzanine Floor Racking

Expands warehouse space vertically.

- Doubles or triples usable storage area

- Strong steel structure supports both people and goods

- Used for offices, picking areas, or multi-level storage

2.9. ASRS (Automated Storage and Retrieval System)

Advanced automation system integrated with software for full warehouse control.

- Reduces human error and increases accuracy

- Real-time inventory management

- Maximizes cubic warehouse capacity

2.10. Very Narrow Aisle (VNA) Racking

High-density racking with minimal aisle width (1.8–2.2m).

- Height up to 17–20m

- 100% direct pallet access

- Compatible with turret or trilateral forklifts

- Ideal for warehouses with limited floor space

3. Heavy-Duty Rack Price Guide 2025

Prices vary depending on rack type, size, material, and load requirements.

To receive an accurate quotation, contact Vinatech Group directly for consultation.

✅ International standards: ISO 9001:2015, ISO 14001:2015, ISO 45001:2015, AS 4084-2023

✅ High-grade steel: POSCO & Hoa Phat

✅ Strict quality control: Welding, coating, and load testing before delivery

✅ Warranty: 5-10 years depending on product type

✅ Free 2D/3D design and on-site survey

4. Why Choose Vinatech Group?

Vinatech Group is a leading manufacturer and installer of industrial storage systems in Vietnam.

Our strengths include:

- 50,000 m² manufacturing plants in both North & South Vietnam

- 500+ experienced engineers and installation experts

- 200+ nationwide distributors and partners

- Over 50,000 successful warehouse projects

- Free consultation, survey, and customized design solutions

Vinatech Group – Vietnam’s No.1 Warehouse Racking Manufacturer

📞 Hotline: 086.758.9999

📧 Email: info@vinatechgroup.vn

🌐 Website: vinatechgroup.vn

Head Offices:

- Hanoi: 15th Floor, TTC Building, 19 Duy Tan, Cau Giay

- Da Nang: 219–223 Pham Hung, Cam Le District

- Ho Chi Minh City: Lot C2-7, N7 Street, Tan Phu Trung IZ, Cu Chi