What is Chemical Warehouse Racking?

Chemical Warehouse Racking is critical for enterprises operating in hazardous materials handling. Chemical warehouse racking systems feature robust construction, high durability, and substantial capacity designed for storing or preserving dangerous goods. However, these systems require regular inspection and maintenance to ensure ongoing safety.

Chemical warehouse racking refers to storage systems for chemicals awaiting further production processes or finished products ready for market distribution.

Chemicals are specialty goods demanding stringent preservation standards. Chemical warehouses require strict protocols ensuring safety while preventing harm to personnel and the environment. Proper racking plays a vital role in scientific chemical management and organization, optimizing space utilization and minimizing storage and handling risks.

Structural Specifications

Chemical racking systems feature sturdy construction engineered to support heavy loads while ensuring safety when storing hazardous materials.

These systems typically utilize high-grade steel with robust omega-profile columns, exterior electrostatic coating providing aesthetic appeal while preventing rust and metal corrosion. Many configurations withstand high temperatures and support medium-to-heavy loads combined with steel pallets offering fire and explosion resistance.

Steel pallet racking extends beyond chemical container and bag storage, offering versatile applications including general warehouse goods, agricultural products, heavy machinery, and industrial components.

Common System Configurations

Pallet-Based Chemical Storage

Pallet systems provide cost-effective solutions for enterprises, positioning pallets across multiple levels. For large, uniform chemicals without stringent preservation requirements, pallet storage is optimal.

This approach saves substantial investment by eliminating dedicated racking infrastructure. Pallets stack neatly with manual or forklift retrieval. Pallet materials include steel, plastic, or wood depending on enterprise requirements.

Additionally, these systems fold compactly for space conservation and relocate easily without compromising warehouse floor aesthetics.

Note: Enterprises should prioritize safety by avoiding excessive pallet stacking height to limit risks.

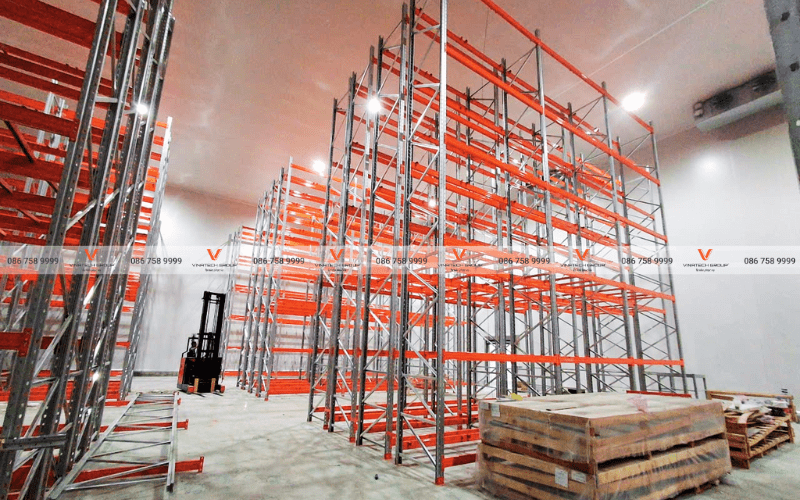

Pallet Racking for Chemical Storage

Pallet Racking systems offer flexibility with rapid inbound/outbound operations, enabling forklift access to all chemical pallets. Selective pallet racking accommodates various pallet dimensions, supporting diverse chemical storage requirements.

For heavy, dangerous chemicals requiring minimal external impact, Selective systems provide optimal solutions.

Enterprises can zone different chemicals within unified systems rather than investing in separate racking for each substance. Heavy-duty chemical Selective racking supports substantial loads (500-1,500 kg/pallet), enabling enterprises to store and preserve large chemical volumes.

Double Deep Chemical Storage

Double Deep racking systems offer efficient solutions for increased storage capacity and facility space conservation. With Selective-derived construction, these systems utilize uniform pallet types combined with specialized forklifts. This configuration suits heavy chemical storage with flexible inbound/outbound operations.

Drive-In Chemical Storage

Drive-In racking systems suit enterprises requiring large-volume storage of uniform chemicals with extended warehousing periods, increasing storage density and facility capacity by minimizing aisle space.

However, forklift access flexibility is reduced versus previous configurations. Systems support two methods: LIFO (Last In, First Out) and FIFO (First In, First Out).

Note: Drive-In systems require uniform pallet dimensions with standard rigidity specifications. For heavy chemical loads, enterprises should utilize steel pallets as wood and plastic alternatives have shorter lifespans without ensuring safety.

Medium-Duty Chemical Shelving

Medium-duty Shelving feature lower capacity (200-500 kg/level), suitable for diverse chemical storage requirements with moderate loads and flexible operations. These systems provide access to all warehouse chemicals, with elevated positions accessible via ladder trucks.

Medium-duty designs incorporate steel decking, panels, and frames. Based on chemical packaging dimensions, design units propose suitable, cost-effective solutions.

Maintenance Importance

Chemical storage immediately suggests toxicity; negligent incidents cause enormous losses affecting not only facility assets and inventory but also all working personnel. Therefore, regular chemical racking maintenance and inspection are critically important.

Beyond compliant, safe warehouse construction, all equipment and materials in chemical storage facilities must meet safety standards.

Numerous factors cause unfortunate incidents: forklift collisions damaging industrial chemical racking columns causing bending or crushing; prolonged usage or overload conditions affecting load-bearing capacity.

After operational periods, chemical racking requires structural inspections verifying load capacity for stored merchandise, checking for loose or corroded components affecting stability and overall structural integrity, ensuring safety for goods, personnel, and entire facilities.

Maintenance Procedures

Industrial chemical warehouse racking requires periodic maintenance for equipment condition assessment and timely repairs when damage occurs. Typically, inspection processes include:

- Inspect complete racking quality including columns, frames, load decks, bolts, and pallets for damage

- Examine warehouse floor conditions for chips, slippery surfaces affecting racking stability

- Assess column and component damage severity, determining replacement necessity versus continued usage

- Inspect beam systems for deformation and damage levels

Following comprehensive racking system inspection, upon discovering damage, do not attempt independent repairs—contact specialists and qualified technicians for assessment and timely, rapid solutions.

Regular chemical warehouse racking inspection and maintenance procedures are essential knowledge for warehouse managers and business owners. When racking becomes irreparable, immediate replacement is necessary to prevent unfortunate incidents.

Vinatech Group: Vietnam’s #1 Chemical Racking Contractor

With 14+ years of experience in warehouse design and construction, Vinatech Group consistently earns trust and selection from enterprises and customers nationwide.

Our warehouse models integrate modern production technology and machinery with highly skilled installation teams. We always propose suitable, optimized racking solutions matching facility scale and chemical warehouse area, maximizing investment efficiency and long-term durability.

Our chemical racking models strictly adhere to international design standards with intelligent, highly aesthetic designs delivering professional warehouse environments that enhance enterprise operational efficiency.

Premium Solutions:

- Advanced manufacturing technology with fully automated production lines ensuring quality standards and precision

- High-grade steel materials with standard thickness specifications

- Competitive pricing with comprehensive warranty coverage

- Expert consultation and installation services

Vinatech Group – Vietnam’s leading warehouse racking and smart storage solution provider

Contact: +84 86 758 9999 | info@vinatechgroup.vn | vinatechgroup.vn

Offices:

- Hanoi: 15F TTC Building, 19 Duy Tan St., Dich Vong, Cau Giay

- Da Nang: 219-223 Pham Hung St., Hoa Xuan, Cam Le

- Ho Chi Minh City: C2-7 N7 Road, Tan Phu Trung IP, Cu Chi