What is Packaging Warehouse Racking?

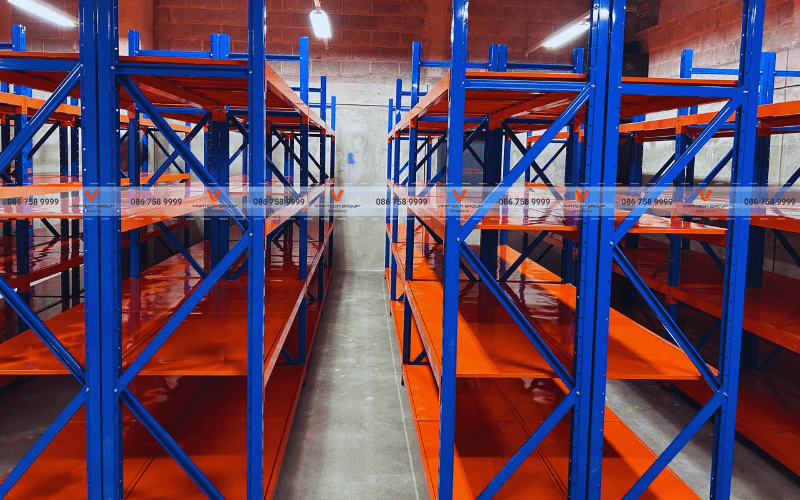

Packaging warehouse racking systems are industrial storage solutions designed to store materials used for wrapping and containing goods. Proper packaging storage protects product value while facilitating movement, warehousing, and distribution.

Packaging storage racking refers to shelving systems designed for paper, cartons, bags, and containers. These systems are manufactured across multiple load capacities—heavy, medium, and light-duty—with robust construction ideal for any industrial warehouse handling packaging materials.

Warehouse Characteristics

Material Diversity

Packaging facilities house varied material types requiring systematic racking for efficient categorization, management, and rapid material flow. Classification systems include:

- Contact-based: inner packaging (direct product contact) versus outer packaging (transport protection)

- Material properties: rigid, semi-rigid, and flexible packaging grades

Environmental Protection

Facilities require secure storage preventing moisture damage and mold formation. Materials must remain elevated above floor level with adequate protection from sunlight, precipitation, and humidity exposure.

Operational Advantages

Material Protection: Racking systems shield packaging from environmental factors (sun, rain, moisture) while preventing floor contact that causes mold and pest infestation.

Capacity Maximization: Intelligent multi-tier designs with adjustable levels enable high-volume storage, optimizing facility capacity up to 70% while preventing moisture-related degradation.

Enhanced Control: For large-scale facilities with diverse inventory, racking enables scientific organization improving monitoring, inventory accuracy, and eliminating material confusion or loss.

System Specifications by Load Category

Heavy-Duty Systems (>500kg/level)

Industrial-grade racking for steel, timber, and palletized materials across multiple warehouse applications.

- Pallet Racking: Best suited for multi-SKU facilities requiring rapid throughput. Specifications: 500-4,000kg/level capacity; 16m maximum height; 100% forklift access to all positions.

- Double Deep racking: Dual-depth design versus standard Selective, doubling storage volume. Trade-off: 50% accessibility requiring specialized reach trucks for interior positions.

- Drive-In racking: Rail-mounted pallet storage enabling deeper placement, maximizing cubic utilization while reducing aisle requirements. Specifications: 1,000kg/pallet; 8m maximum height.

- …

Medium-duty Shelving (200-500kg/level)

Multi-level configurations with steel or plywood decking per tier. Provides 100% position accessibility, suitable for packaging facilities where storage density is secondary to access requirements.

V-Rack Vinatech (70<<100kg/level)

Beyond lightweight packaging applications, these units accommodate document archiving, household storage, and retail merchandising.

V-Rack Vinatech: Advanced alternative to conventional slotted angle systems, offering accelerated installation via bolt-free snap-assembly versus traditional fastener-dependent designs.

Vinatech Group Value Proposition

As a premier industrial racking, steel pallet, and auxiliary warehouse equipment manufacturer, we deliver comprehensive packaging storage solutions (Selective, Double Deep, medium-duty systems) meeting diverse requirements with guarantees including:

- Premium steel construction engineered for heavy loads with extended operational lifespan

- Customized designs optimized for facility dimensions and operational requirements with complimentary consultation and installation planning

- Comprehensive 5-year warranty and maintenance program

Vinatech Group – Vietnam’s leading warehouse racking and smart storage solution provider

Contact: +84 86 758 9999 | info@vinatechgroup.vn | vinatechgroup.vn

Locations:

- Hanoi: 15F TTC Building, 19 Duy Tan St., Dich Vong, Cau Giay

- Da Nang: 219-223 Pham Hung St., Hoa Xuan, Cam Le

- Ho Chi Minh City: C2-7 N7 Road, Tan Phu Trung IP, Cu Chi