Vinatech Group delivers industrial-standard warehouse racking solutions for Da Nang enterprises with diverse configurations including Selective, Medium-Duty, V-Slot, Drive-In, and Double Deep systems at competitive 2025 pricing. Join Vinatech Group to find out the price quote for Warehouse Racking Da Nang here.

2025 Pricing Overview Vinatech Group

| System Type | Price (VND/Unit) | Load Capacity | Space Optimization | Best For |

|---|---|---|---|---|

| V-Slot Steel | 800K – 3.5M | 70-100 kg/level | 65-75% | Offices, retail |

| Medium-duty Shelving | 1.2M – 5M | 200-500 kg/level | 50-60% | Small industrial facilities |

| Pallet Racking | 8M – 25M | 1,000-3,000 kg/level | 40-50% | Logistics, distribution |

| Double Deep racking | 14M – 32M | 1,500-3,000 kg/level | 60-70% | High-density storage |

| Drive-In racking | 12M – 40M | 1,000-3,000 kg/pallet | 75-85% | Cold storage, batch goods |

Industrial Racking Systems

V-Slot Steel Shelving

Trusted by Da Nang businesses, offices, and retail stores for rapid assembly without bolts, completing installation in 15-30 minutes. Flexible design suits document archives, showrooms, electronics stores, and parts storage in central districts.

Technical Specifications:

- Load capacity: 70-100 kg/level

- Material: 100% Q235 cold-rolled steel with CO/CQ certification

- Surface treatment: 7-layer electrostatic coating, 60-80 micron thickness

- Color options: Black, white, grey, or custom

- Service life: 15+ years

Medium-Duty Shelving

Medium-duty Shelving suitable for 70%+ of Da Nang small-to-medium enterprises. Flexible 3-6 tier designs accommodate electronics components, automotive parts, consumer goods, and industrial supplies. Projects exceeding 500 million VND receive custom design support.

Technical Specifications:

- Load capacity: 200-500 kg/level

- Tiers: 3-6 levels, easily adjustable

- Material: 100% Q235 cold-rolled steel, CO-CQ certified

- Electrostatic coating: 7 layers, 10+ year color retention

- Retrieval methods: Manual, hand truck, or forklift

- Inventory management: LIFO/FIFO

- Service life: 15+ years

Selective Pallet Racking

The most widely adopted industrial racking system, providing 100% direct pallet access without relocating other pallets. Designed for logistics centers, distribution hubs, raw material, food, and pharmaceutical warehouses, ensuring FIFO compliance while optimizing throughput and reducing search time by 50%.

Technical Specifications:

- Load capacity: 1,000-3,000 kg/pallet

- Height: 4,000-12,000 mm

- Pallet dimensions: 1000×1200 mm or 1200×1200 mm

- Material: 100% Q235 cold-rolled steel with CO-CQ certification

- Electrostatic coating: 7 layers, 60-80 micron thickness

- Warehouse utilization: 40-50%

- Retrieval access: 100% (FIFO/LIFO)

- Equipment: Reach truck, counterbalance forklift

- Service life: 15+ years

Double Deep Racking

Heavy-duty systems configured with 2-pallet depth, increasing storage density 60-70% while reducing aisle requirements by half versus Selective systems. Ideal for Da Nang enterprises with limited facility space requiring high-volume storage of homogeneous goods.

Technical Specifications:

- Load capacity: 1,500-2,000 kg/pallet

- Height: 5,000-11,000 mm

- Depth: 2 pallets (~2,400 mm)

- Material: 100% Q235 cold-rolled steel with CO-CQ certification

- Electrostatic coating: 7 layers, corrosion-resistant

- Fill efficiency: 60-70%

- Retrieval access: 50%

- Management method: LIFO (Last In, First Out)

- Equipment: Double deep reach truck

- Service life: 15+ years

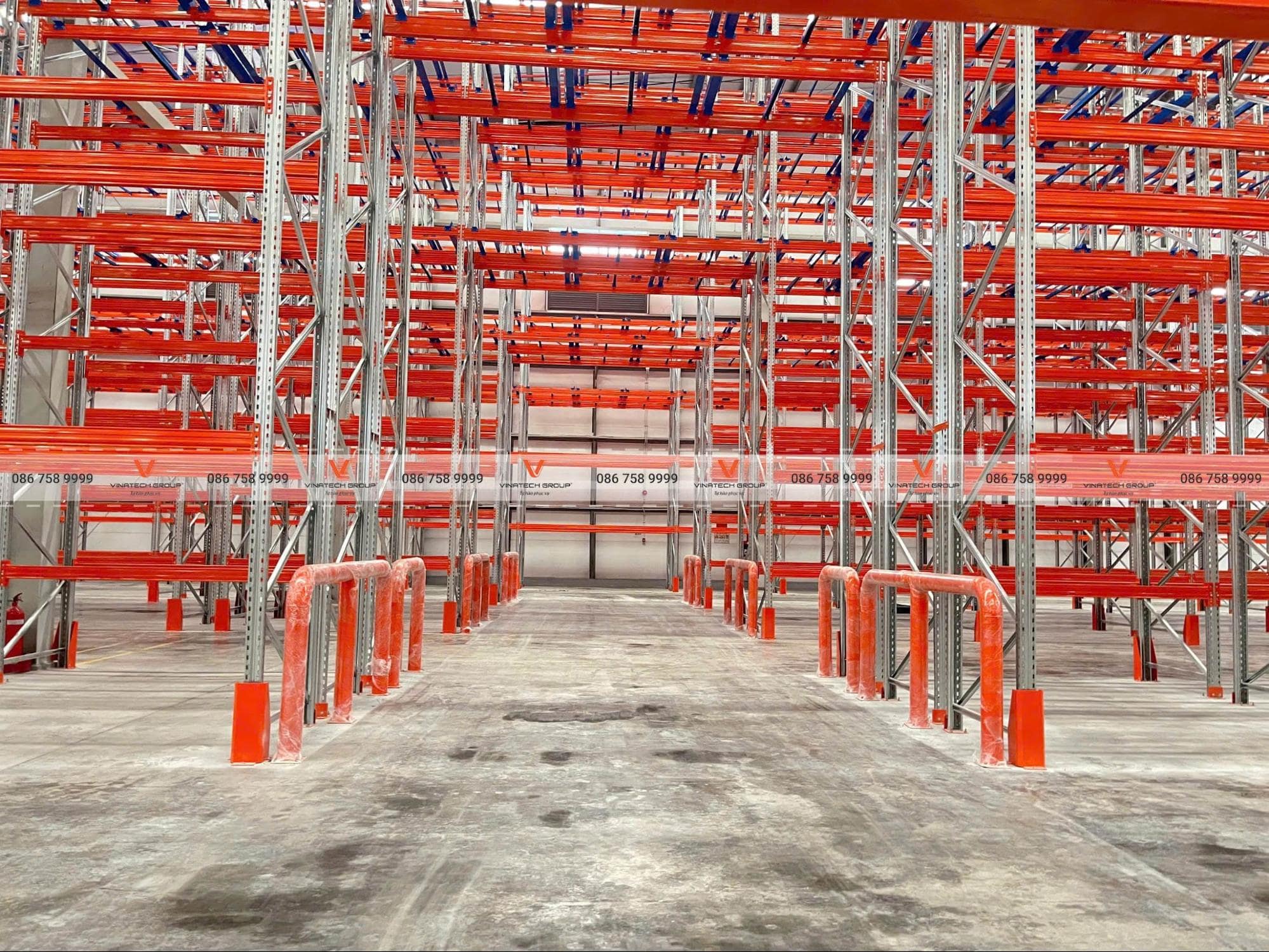

Drive-In Racking

Specialized heavy-duty systems for large-batch, low-SKU inventory allowing forklifts to drive directly into rack lanes for material handling. Design increases storage density to 75-85% of facility area while reducing cold storage cooling costs by 60% through minimized aisle space—optimal for Da Nang manufacturing, food, beverage, and cold storage operations.

Technical Specifications:

- Load capacity: 1,000-3,000 kg/pallet

- Lane depth: 5-10 consecutive pallets

- Material: 100% Q235 cold-rolled steel with CO-CQ certification

- Electrostatic coating: 7 layers, temperature range –25°C to +50°C

- Fill efficiency: 75-85%

- Storage methods:

- Drive-In: LIFO (Last In, First Out)

- Drive-Through: FIFO (First In, First Out)

- Service life: 15+ years

Vinatech Group Quality Standards

With 14 years of experience and 1,000+ successful Vietnamese projects, Vinatech Group guarantees premium quality, safety, and environmental compliance:

Superior Materials:

- 100% cold-rolled steel with CO-CQ certification, 15-20% stronger than hot-rolled alternatives, rust-resistant with 15+ year lifespan

- 7-layer automated electrostatic coating, 60-80 micron thickness, 10+ year color retention without peeling

Certifications:

- ISO 9001:2015 (Quality Management)

- ISO 14001:2015 (Environmental Management)

- ISO 45001:2018 (Occupational Health & Safety)

Service Excellence:

- Rapid completion: 20-30 day installation, 30-50% faster than competitors

- Extended warranty: 5-10 years covering frames, coating, and connections

- Complimentary maintenance: Twice yearly for 100+ unit orders with periodic inspection and servicing

VINATECH VIETNAM GROUP JOINT STOCK COMPANY

Contact: +84 86 758 9999 | info@vinatechgroup.vn | vinatechgroup.vn

Offices:

- Hanoi: TTC Building, Duy Tan, Dich Vong, Cau Giay

- Ho Chi Minh City: C2-7 N7 Road, Tan Phu Trung IP, Cu Chi

- Da Nang: 219-223 Pham Hung St., Hoa Xuan, Cam Le

Manufacturing Facilities:

- Northern: Tam Hiep, Phuc Tho, Hanoi

- Southern: Tan Phu Trung IP, Cu Chi, HCMC