Cold storage racking is a heavy-duty shelving system designed to preserve food products, agricultural produce, fruits, seafood, vegetables, pharmaceuticals, and more at low temperatures. These frozen warehouse racking systems help investors optimize space, enhance operational efficiency, achieve perfect temperature control, and generate significant cost savings. With 14 years of experience in cold storage racking installation, join Vinatech Group to explore warehouse shelving models suitable for cold environments and detailed pricing information!

What is Cold Storage Racking?

Cold storage racking refers to specialized storage shelving used for keeping goods in sub-zero temperature environments. Made from heat-resistant iron and steel materials, these systems can operate in cold environments down to -60°C.

Cold storage racking is a specialized shelving system specifically engineered to store goods in low-temperature environments ranging from 0°C to -25°C, even reaching -30°C.

These warehouse racking utilize anti-oxidation materials and robust construction, ensuring stable operation in prolonged cold and humid conditions, while still allowing storage of large, heavy palletized goods in substantial quantities.

Common product categories typically stored in cold storage racking include seafood, food products, vegetables and fruits, and certain specialized items requiring low-temperature environments.

Upgrading warehouse racking has become a critical factor helping businesses increase competitiveness, especially cold storage racking in the food industry, pharmaceutical preservation, and similar sectors.

Cold storage shelving systems are manufactured from cold-resistant materials that don’t deteriorate over extended periods and adapt well to the specific characteristics of low or extremely low temperatures in cold storage facilities.

Advantages of Frozen Warehouse Racking

In cold storage environments – particularly freezers preserving food products, seafood, pharmaceuticals, etc. – shelving systems must not only ensure load-bearing capacity but also adapt effectively to harsh temperature conditions.

- Withstands deep freezing temperatures (-25°C to -40°C)

- Superior rust and corrosion resistance

- Reduces heat loss, saves energy costs

- Optimizes storage area in freezer warehouses

- Flexible racking assembly and disassembly

- Cold storage racking offers flexibility in assembly and disassembly

REFERENCE MULTI-INDUSTRY APPLICATIONS:

- Material storage warehouse racking

- Pharmaceutical warehouse racking

- Mechanical warehouse racking

7+ Popular Cold Storage Racking Models Currently Available

Heavy duty racking systems suitable for cold storage typically include pallet rack types such as drive-in racks, mobile racking, selective racks, and others. These racks feature durable construction, withstand low temperatures, and offer lasting quality that optimizes operational efficiency in cold storage facilities. Specifically:

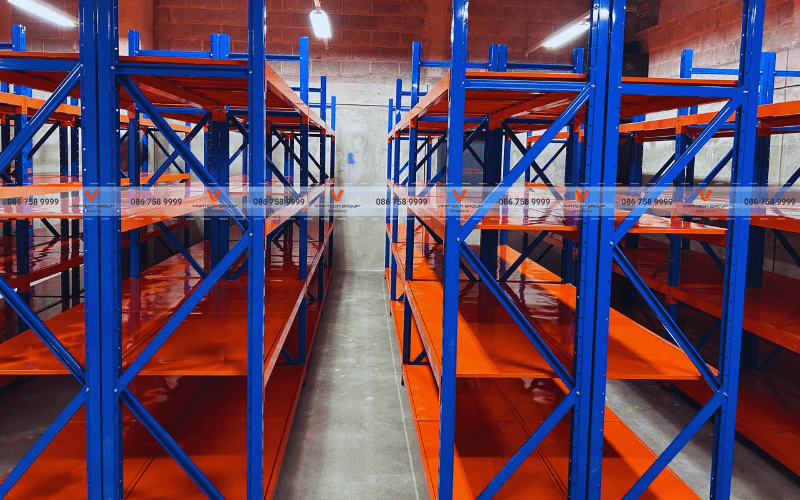

Medium-Duty Cold Storage Racking

Medium-duty racking represents one of the most popular storage solutions currently used in industrial warehouse systems, particularly effective for cold storage due to its load capacity of up to 600kg per tier. This is the optimal choice for businesses requiring high-density storage of medium-weight goods.

Medium-duty racking models for cold storage require compact, lightweight construction, easy installation, simple dimensional adjustments, and flexible space configuration.

Additionally, medium-duty racking can integrate with various other rack types in hybrid warehouse systems, depending on specific floor plan characteristics or particular operational methods.

Medium-duty racking suits not only cold storage but also finds widespread application in dry warehouses, manufacturing warehouses, material warehouses, and technical parts storage, thanks to its stability and flexibility.

Frozen Warehouse Shuttle Racking

Shuttle racking for cold storage is an intelligent semi-automated storage solution integrating goods transfer robots moving on rails, controlled by remote or computer systems.

With load capacities of 500-1500kg/pallet, stable operation in environments from -30°C to +40°C, this racking system particularly suits cold storage facilities with high volume throughput or seasonal operations.

Shuttle robots achieve speeds of 1.2 m/s (unloaded) and 0.8 m/s (loaded), allowing storage of up to 30 pallet levels, depths reaching 40m, helping increase storage capacity by up to 80% of cold storage space.

Selective Cold Storage Racking

In modern cold storage racking systems, Selective racking is rated as the optimal choice thanks to flexible storage capability and high durability.

With load capacity exceeding 500kg/pallet, this rack type effectively meets preservation needs for diverse product categories such as frozen foods, pharmaceuticals, processed agricultural products, etc.

Selective racking for cold storage is typically fabricated using powder-coated steel or hot-dip galvanized materials to enhance corrosion resistance in low-temperature, high-humidity environments.

Simple design and easy assembly help optimize construction and maintenance time, while reducing investment costs compared to complex automated racking systems.

The standout advantage of Selective pallet racking for cold storage is allowing forklifts direct 100% access to each pallet, facilitating easy input/output following FIFO or LIFO methods – critically important for goods with expiration dates.

However, since aisle space is required for forklift access, this solution better suits cold storage facilities with medium to large floor areas.

Push Back Cold Storage Steel Racking

Push Back racking for cold storage is a heavy-duty storage solution with capacity for 2-5 pallets per slide lane, helping optimize warehouse space by up to 70% without requiring forklifts to enter deep into the racking. The system operates on LIFO principles, suitable for cold storage with high product volumes not requiring continuous turnover.

With intelligent slide-back design, Push Back saves input/output time and offers easy installation, accommodating various pallet types. However, initial investment costs are high and the system doesn’t suit operations requiring FIFO management.

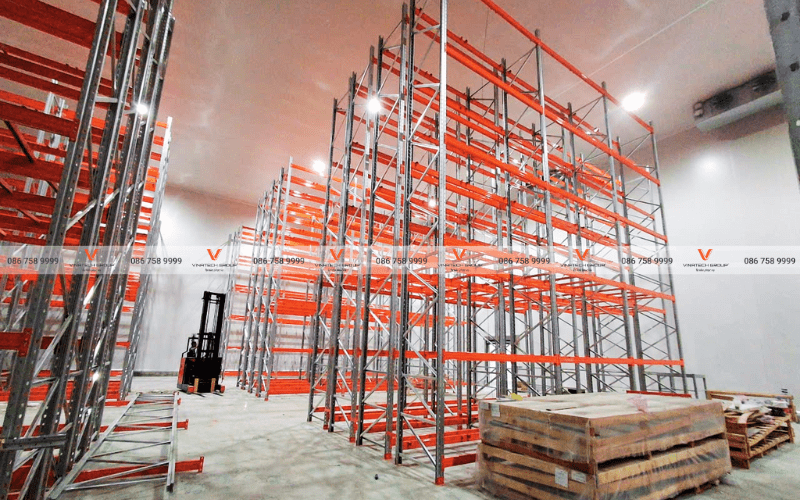

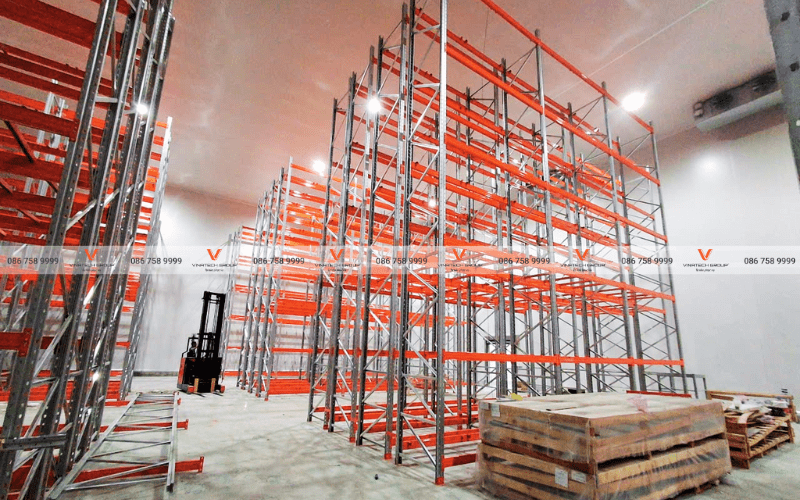

Drive-In Cold Storage Racking

Drive-in racking is among the heavy-duty cold storage racking lines widely applied in current industrial warehouse systems, especially cold storage, food warehouses, seafood facilities, and logistics operations.

With load capacity from 2000-3000kg per tier, Drive-in racking suits warehouses with large product volumes but limited product variety (SKU count).

This racking system follows a multi-tier “drive-in deep” design, allowing forklifts to move directly inside rack rows to stack or retrieve pallets.

Consequently, aisle area is minimized, helping increase actual storage capacity up to 80% of warehouse floor space.

Notably, racks are constructed according to FEM (European) standards for industrial racking structural safety, ensuring high durability and stability in sub-zero temperature environments.

However, for effective and safe system operation, pallets used must be uniform in dimensions and load capacity to ensure forklifts encounter no obstacles when moving deep into the racking.

Double Deep Cold Storage Steel Racking

Double Deep racking is the optimal choice for cold storage requiring large-volume goods storage while maintaining relatively flexible access capability.

Constructed from two Selective rack rows installed back-to-back, this system allows two-pallet-deep storage, helping increase storage density by up to 50% compared to standard Selective racking.

In cold storage environments, Double Deep heavy-duty racking typically receives surface treatment with cold-resistant powder coating or hot-dip galvanizing to prevent rust and ensure high durability under low-temperature, high-humidity conditions.

Suited to LIFO (last in, first out) storage principles, this rack type is ideal for frozen goods with long shelf life such as processed foods, frozen meat and fish, raw materials, etc.

Double Deep cold storage steel racking can handle loads up to 4000kg/tier, meeting large-volume preservation requirements. However, this system requires specialized forklifts with extended forks to access inner pallets, therefore requiring design and operation by experienced warehouse teams.

Latest 2025 Cold Storage Racking Installation Pricing

To help customers preliminarily estimate installation costs and investment for designing professional cold product storage warehouses, Vinatech Group provides a reference price list for current cold storage racking:

Latest 2025 Cold Storage Racking Price List

| Racking Type | Selling Price (VND/set) |

|---|---|

| Drive-in racking for cold storage | 2,500,000 – 5,000,000 VND/set |

| Double Deep racking for cold storage | 2,500,000 – 5,000,000 VND/set |

| VNA racking for cold storage | 2,500,000 – 5,500,000 VND/set |

| Selective racking for cold storage | 2,500,000 – 5,000,000 VND/set |

| Mobile racking for cold storage | Contact us |

Note:

- This price list is for reference purposes, as technical specifications and specific requirements vary by warehouse facility, resulting in different cold storage racking designs.

- For accurate updates on authentic cold storage racking pricing, please contact Vinatech Group’s hotline directly for the most detailed support and consultation!

Vinatech Group – Trusted Cold Storage Steel Racking Installation Provider

Vinatech Group currently leads the market as a specialist in cold storage racking design and construction.

Vinatech Group has many years of experience with annual warehouse racking production and supply capacity. Vinatech Group has provided optimal cold storage racking solutions for thousands of domestic and international enterprises. Vinatech Group’s advantages:

✅ Owns two modern factories in the North and South with total area reaching 50,000 m²

✅ Has over 200 dealers across provinces and cities along with a team of 500 experienced workers, ready to provide consultation, installation, and professional warranty services quickly.

✅ To date, Vinatech Group has successfully completed over 50,000+ projects nationwide, serving diverse industries and business models.

✅ Equipped with closed automated production lines, meeting all large-scale racking production needs ISO 9001:2015. Uses automatic welding robots, roll forming machines, laser cutting machines – ensuring precision and uniformity of each component.

✅ Uses automatic powder coating creating smooth surface coverage, preventing oxidation, extending rack lifespan.

✅ Grade 1 SPCC Posco cold-rolled steel – meeting international standards for load-bearing capacity and deformation resistance.

✅ Partner with many major market entities including: Lotte Mart, PepsiCo, AEON Mall, Winmart, FPT AI IS, and more.

In reality, cold storage racking is indispensable equipment, playing a critical role in creating stable storage environments and ensuring quality of frozen products.

Vinatech Group is Vietnam’s leading manufacturer and provider of warehouse racking and smart warehouse solutions

Hotline: 086.758.9999

Email: info@vinatechgroup.vn

Website: vinatechgroup.vn

Office System:

- Hanoi: 15th Floor, TTC Building, No. 19 Duy Tan Street, Dich Vong, Cau Giay, Hanoi

- Da Nang: 219-223 Pham Hung Street, Hoa Xuan, Cam Le, Da Nang

- Ho Chi Minh City: Lot C2-7, N7 Road, Tan Phu Trung Industrial Park, Cu Chi District, Ho Chi Minh City