Pallet racking is the optimal storage solution for maximizing warehouse productivity and efficiency. Steel pallet racking systems enable safer, more effective inventory storage while elevating operational performance. This comprehensive guide covers the best pallet racking types available and provides updated 2025 pricing information. join Vinatech Group to explore pricing information!

What Is Pallet Racking?

Pallet racking is a steel support system designed to store goods placed on pallets. Widely used in warehouses and storage facilities, these systems optimize space utilization, improve inventory management capabilities, and enhance operational efficiency for businesses.

Pallet storage systems not only preserve and store inventory but also streamline inbound/outbound operations when combined with forklifts, conveyors, or other specialized warehouse equipment.

Average pallet load capacity ranges from 500-2000kg. Plastic and steel pallets are the most commonly used types in these warehouses due to their robust construction and stable load-bearing capabilities.

Types of Steel Pallet Racking

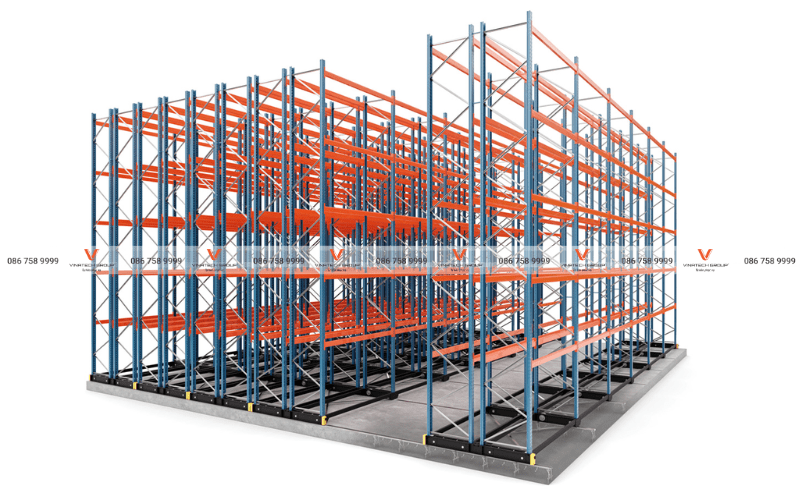

Drive-In Pallet Racking

Drive-In racking is currently a popular choice for heavy-duty cold storage systems, particularly suitable for food, seafood, and logistics industries.

With load capacity up to 3000kg per level, this pallet racking effectively meets high-volume storage needs for limited SKU varieties. Drive-In racking follows a drive-in racking system structure complying with FEM safety standards, optimizing warehouse floor space.

By minimizing forklift aisles, Drive-In pallet racking systems can increase storage capacity up to 80% compared to traditional racking types.

Selective Pallet Racking

As one of the most common pallet racking types on the market, Selective racking is often called “universal racking” due to its widespread application and high efficiency.

Selective pallet racking is trusted by numerous businesses across e-commerce, logistics, food, automotive, mechanical, pharmaceutical, and many other industries.

Simple structure and easy installation are outstanding advantages of Selective steel racking. Lower initial investment costs compared to many other racking systems help businesses save budget while ensuring storage efficiency.

Selective warehouse racking systems support FIFO (First In, First Out) or LIFO (Last In, First Out) loading methods, allowing forklifts direct access to 100% of inventory at all positions—convenient for inventory counting and frequent product rotation.

Double Deep Pallet Racking

With flexible load capacity up to 4000kg/level, Double Deep steel pallet racking suits storing heavy, bulky goods and is appropriate for medium and large warehouse spaces.

However, due to its two-deep tier design characteristics, this system requires specialized long-reach forklifts for precise and safe operations.

While increasing storage density, Double Deep racking reduces direct access capability to individual pallets, making it most suitable for homogeneous goods with clear rotation lifecycles.

Flow Rack (Pallet Flow Rack)

Flow racks have load capacity from 1000-2000kg/pallet, using plastic or steel rollers allowing goods to slide forward by gravity without electricity or labor.

Suitable for cold storage, distribution centers, food, and pharmaceuticals, this system enables rapid product rotation and easy inventory control. The design with 2 separate aisles increases warehouse utilization efficiency up to 75%.

Racks can integrate with Shuttle Rack or ASRS systems but require periodic maintenance and professional installation.

Push Back Pallet Racking

Push Back racking is a heavy-duty storage solution with capacity to store 2-5 pallets per racking lane using pallet cart sliding systems.

Compared to Drive-In racking, Push Back optimizes retrieval time since forklifts don’t need to enter deep into racks.

This pallet racking type increases storage area up to 70%, accommodates various pallet types, offers easy installation, and has low maintenance costs.

However, racks operate on LIFO principles, product rotation speed isn’t high, and require substantial initial investment.

Shuttle Pallet Racking

Leading modern modular warehouse racking systems, automated Shuttle racking is rated as the optimal semi-automated solution for pallet storage.

This system uses 180-220kg transfer robots moving on rails to place/retrieve pallets from racks, operated by remote control or tablet computers.

Shuttle pallet racking has load capacity of 500-2500kg/pallet, suitable for cold storage, high inbound/outbound volume warehouses, and seasonal storage thanks to temperature tolerance from -30 to 40°C.

With superior performance, rapid goods circulation capability, and flexible FIFO/LIFO management methods, Shuttle pallet racking is an ideal choice for businesses in food, beverage, and large-scale industrial warehouse sectors.

Mobile Warehouse Racking

Mobile racking intelligent warehouse systems increase pallet storage capacity 80-120% compared to conventional pallet racking, saving up to 40% usable warehouse space without expansion or floor area increases.

Heavy-duty racking systems suit cold storage setup, high pallet density storage warehouses, and facilities with numerous product SKUs.

VNA Pallet Racking

VNA racking is a pallet storage system with super-narrow aisle design under 2.2m, maximizing floor space utilization and increasing storage capacity up to 40% compared to conventional racking. Racks can stack goods to maximum heights of 17m, suitable for high-ceiling but limited-area warehouses.

Rack construction resembles Selective systems, still ensuring direct access to individual pallets but optimized for efficient operation in small spaces. Due to narrow aisle characteristics, VNA racking requires specialized three-directional forklifts capable of rotating and maneuvering flexibly in limited spaces.

An ideal choice for warehouses with large heights needing to maximize vertical storage, VNA pallet racking is prioritized by many businesses in logistics, pharmaceuticals, and food sectors.

Pallet Racking System Components

Industrial pallet racking construction isn’t complex but requires precise installation to ensure load capacity, safety, and longevity:

- Upright posts: Main load-bearing components for entire pallet racking systems, interconnected by horizontal and diagonal bracing beams

- Beams: Connect two upright posts, serving as pallet support bases

- Bracing: Including diagonal and horizontal bracing increasing overall frame rigidity, preventing vibration and collapse during forklift operations

- Base plates & expansion bolts: Secure upright frames to warehouse floors using M10 or M12 bolts, with optional wide base plates, rubber pads, or impact protection posts in forklift warehouses

- Pallet contact surfaces / sliding rails (if applicable): Bear entire pallet weight

Pallet Racking Selection Considerations

- Inbound/outbound requirements: Consider quantity, product types, weight, and dimensions to select appropriate racking. This optimizes storage capacity while ensuring inventory safety and facilitating easy, rapid inbound/outbound operations.

- Standard-compliant racking structure: When selecting steel pallet or any pallet racking type, carefully evaluate structure to ensure standard compliance for absolute accuracy and safety guarantee, since each warehouse has different product categories requiring specific load capacities and scales.

- Professional installation provider: The best and fastest way to select appropriate pallet racking is finding professional manufacturing, supply, and installation providers. With extensive experience, they’ll provide optimal solutions matching storage requirements.

- Investment budget: Consider budget to select appropriate racking types.

2025 Updated Pallet Racking Pricing

Vinatech Group is a trusted provider specializing in industry-leading durable industrial pallet racking systems. Vinatech Group pallet racking has been independently tested and certified with international quality standards including ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018.

Latest 2025 genuine Vinatech Group pallet racking price list:

| Pallet Racking Type | Price (VND/unit) |

|---|---|

| Selective pallet racking | From 2,500,000 |

| Double Deep pallet racking | From 2,500,000 |

| Drive-In pallet racking | From 3,000,000 |

| Mobile pallet racking | Contact |

| Flow pallet racking | From 3,000,000 |

| Shuttle pallet racking | Contact |

| Push Back pallet racking | Contact |

Pallet warehouse racking prices depend on various factors including rack dimensions, quantities, thickness, and paint colors. Vinatech Group manufactures custom non-standard specification racking with large orders receiving free design support.

Vinatech Group – Trusted Pallet Racking Design & Installation

Vinatech Group Joint Stock Company proudly operates with over 14 years of experience in warehouse design consulting. Thousands of business clients have trusted and selected Vinatech Group as their pallet racking setup consulting partner.

Why choose Vinatech Group:

- Modern automated production lines: Welding robots, CNC laser cutting, high-speed punching-rolling systems

- Fire safety compliance and warehouse regulations adherence

- 5-10 year warranty depending on product lines

- Personnel training support for operations and rack maintenance

- 2 large factories in North-South regions, total area nearly 50,000m²

- Genuine grade I steel from Posco and Hoa Phat

- Thorough inspection of welds, paint layers, thickness before factory delivery

- Direct testing and transportation from factory to construction sites

- Free 2D, 3D design consultation

Vinatech Group — Leading manufacturer and provider of warehouse racking and smart storage solutions in Vietnam

📞 Hotline: 086.758.9999

📧 Email: info@vinatechgroup.vn

🌐 Website: vinatechgroup.vn

Office locations:

- Hanoi: 15th Floor, TTC Building, 19 Duy Tan Street, Dich Vong, Cau Giay District

- Da Nang: 219-223 Pham Hung Street, Hoa Xuan, Cam Le District

- Ho Chi Minh City: Lot C2-7, N7 Road, Tan Phu Trung Industrial Park, Cu Chi District