Push Back Racking is rapidly becoming the preferred high-density storage solution for modern manufacturing plants, cold storage facilities, and distribution centers. By leveraging depth and a gravity-fed design, this system offers a powerful blend of space optimization and operational efficiency. Discover the comprehensive benefits, technical details, and investment value of Push Back Racking with Vinatech Group, Vietnam’s leading storage solutions provider.

What is Push Back Racking?

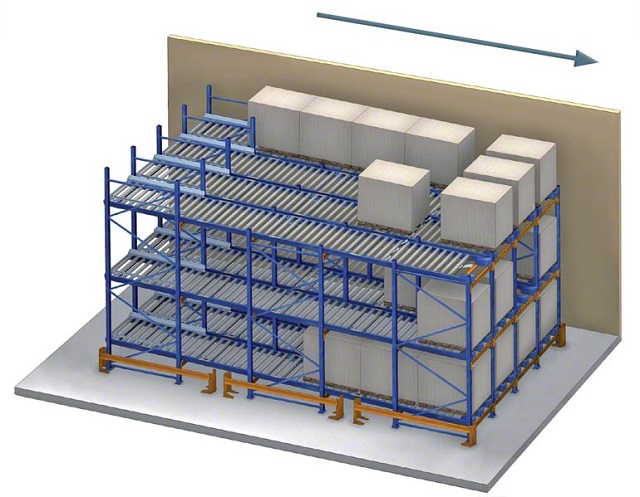

Push Back Racking is an industrial pallet storage system that utilizes depth to increase capacity, typically accommodating 2 to 5 pallets per lane. It features a set of nested, wheeled carts that ride on inclined rails. When a new pallet is loaded, it gently “pushes back” the pallet already in the lane. When a pallet is unloaded, the rear pallets automatically glide forward to the picking face.

This system operates on the LIFO (Last-In, First-Out) principle, where the last pallet loaded is the first one available for retrieval.

Compared to standard Selective racking, a Push Back system can increase storage density by 2 to 3 times while maintaining high-speed, safe, and straightforward operations. It is an ideal solution for facilities in the FMCG, 3PL/logistics, and cold storage sectors, especially those with high-turnover inventory that does not require strict FIFO management.

Core Components of the Push Back System

A Push Back system’s reliability comes from its precision-engineered components, designed to work together seamlessly:

- Upright Frames: The primary load-bearing structure, manufactured from cold-rolled steel and finished with a durable powder coat or galvanized coating for rust prevention.

- Load Beams: Connect the upright frames and provide direct support for the rail and cart system.

- Nested Carts: A series of wheeled carts that nest within each other. Each cart supports a single pallet and rolls smoothly along the rails.

- Inclined Rails: The foundation of the system. The rails are set at a slight incline (typically 2-4 degrees), allowing gravity to automatically bring pallets to the front picking face during unloading.

- Pallet Stoppers: Heavy-duty steel stops located at the front of the lane to safely secure the front pallet and prevent it from rolling off.

- Braking System (Optional): Dampeners or brakes can be integrated to control the speed of descending pallets, preventing impacts and enhancing safety.

- Post Protectors: Guards installed at the base of the uprights to protect the system from forklift collisions.

Technical Specifications

Vinatech Group’s Push Back racking systems are engineered to the highest standards for performance and safety.

| Specification | Details |

| Upright Profile (Omega) | 68 x 90 x 1.5 mm |

| Load Capacity per Pallet | 500 – 1,500 kg |

| Maximum System Height | 10 meters |

| Material | High-Tensile, Cold-Rolled Steel |

| Surface Finish | Powder Coating |

| Standard Warranty | 12 Months |

| Standard Colors | Blue & Orange (Customizable) |

Key Advantages of Push Back Racking

- Superior Storage Density: By utilizing lane depth for storage, the system reduces the number of required aisles, increasing storage capacity by 50% to 100% over Selective racking in the same footprint.

- Increased Operational Speed: Forklifts do not need to enter the racking structure. This significantly speeds up loading and unloading times and reduces the risk of rack damage.

- High Pallet Flexibility: Unlike Drive-In systems, each pallet rests on its own cart, meaning pallets do not need to be of uniform size or quality.

- Enhanced Safety and Durability: The robust steel construction, combined with safety features like stoppers and protectors, ensures a long operational life of 15-20 years with proper use.

- Scalable and Modular: The system’s design allows for easy expansion. Lanes can be added, and levels can be adjusted to accommodate future growth.

Important Considerations & Limitations

- Strict LIFO Operation: The system is not suitable for products requiring strict FIFO (First-In, First-Out) inventory management, such as perishable goods or pharmaceuticals with near-term expiration dates.

- Higher Initial Investment: Due to the specialized carts, rails, and precision engineering, the initial investment is typically 20-30% higher than a standard Selective rack system. However, this cost is often offset by long-term savings in real estate and operational efficiency.

- Limited Intra-Lane Selectivity: To access a pallet at the back of a lane, all pallets in front of it must be removed first. This makes it unsuitable for operations that require random access to specific pallets within a single lane.

- Requires Expert Installation: Proper function depends on the precise alignment and calibration of the inclined rails and carts, demanding experienced and skilled installation technicians.

Comparison: Push Back vs. Drive-In Racking

Many businesses consider both Push Back and Drive-In for high-density storage. Here is a clear comparison to help you decide:

| Feature | Push Back Racking | Drive-In Racking |

| Operating Principle | LIFO | LIFO |

| Selectivity | Good: Every lane face can hold a different SKU. | Poor: An entire bay must be dedicated to a single SKU. |

| Operating Speed | Fast: Forklift operates from the aisle. | Slow: Forklift must carefully drive into the structure. |

| Risk of Damage | Low: Minimal interaction between forklift and rack. | High: Frequent potential for collisions inside the structure. |

| Pallet Flexibility | High: Each pallet has its own cart. | Low: Requires uniform, high-quality pallets to sit on rails. |

| Storage Density | Very High | Maximum |

Investment and Pricing for Push Back Racking

The investment for a Push Back system is dynamic and calculated on a per-pallet-position basis. The final price can range from $100 USD per pallet position and upwards, depending on factors such as:

- The number of pallet positions and lane depth.

- The required load capacity and system height.

- The complexity of the project and specific site requirements.

For an accurate and competitive quote, please contact the Vinatech team. Hotline: 086.758.9999

Why Choose Vinatech Group for Your Push Back Racking Project?

With over 14 years of experience, Vinatech Group is Vietnam’s premier manufacturer and installer of advanced warehouse storage systems.

- Factory-Direct Manufacturing: We control the entire production process in-house, ensuring superior quality, faster lead times, and better value.

- 3,000+ Successful Projects: Our expert technical team has successfully designed and installed Push Back systems for leading companies in FMCG, food processing, cold storage, and logistics.

- Customized Solutions: Every project begins with a thorough site survey and a detailed 2D/3D design to ensure the solution is perfectly optimized for your space and workflow.

- Comprehensive Warranty & Support: We offer an extensive 5-10 month warranty and provide long-term support, including periodic inspections and prompt maintenance.

- Nationwide Installation: Our in-house installation teams handle everything from transport to final commissioning, ensuring a seamless and high-quality setup anywhere in Vietnam.

Vinatech là đơn vị sản xuất giá kệ kho hàng, kệ siêu thị lớn nhất Việt Nam hiện nay, với rất nhiều mẫu sản phẩm giá kệ chất lượng hàng đầu.